Ductility (or formability) is a key material property that determines whether a metal can be processed. Highly ductile materials like aluminum alloys are easily processed through different types of metalworking processes, while stainless steel can be more difficult to work with. These materials form the basis of metal fabrication work across industries.

Carbon Steel

Due to its properties, you can use carbon steel in various industries. You can use these metals in construction, machine assembly, and other high-end applications. They are versatile and can withstand various working conditions. Besides these advantages, carbon steel is also very durable and resistant to wear and tear.

Aluminum Sheets

This lightweight metal is suitable for manufacturing. Due to its low density, aluminum is used in the aerospace and automotive industries. This is because maintaining low weight is important in these applications. It has a high strength-to-weight ratio and good thermal properties, which makes it perform well in almost all applications.

Bronze

Among metals, bronze is a less popular choice. This material contains a significant amount of tin. Additionally, bronze is wear-resistant and corrosion-resistant. As a good conductor of heat and electricity, this material is ideal for manufacturing.

Brass Alloys

Brass alloys are a mixture of zinc and copper. These metals are ductile and have a low melting point. Their reddish color sets them apart from other metals. Due to their aesthetic appeal, you can use them in applications where appearance is important.

Furthermore, brass alloys have antibacterial properties, making them very useful in the medical industry. You can use this material to combat diseases. Additionally, you can customize this metal based on its composition.

Stainless Steel

Stainless steel is known for its corrosion resistance, rust resistance, and durability. It has a fine mirror finish, which enhances its appeal. Therefore, it is highly favored among manufacturers. Furthermore, you can bend and weld this metal as needed.

Copper

This metal can be used without additional processing. Copper has properties such as good thermal and electrical conductivity, ductility, softness, tensile strength, and malleability. Due to these properties, you can use copper in many high-performance applications.

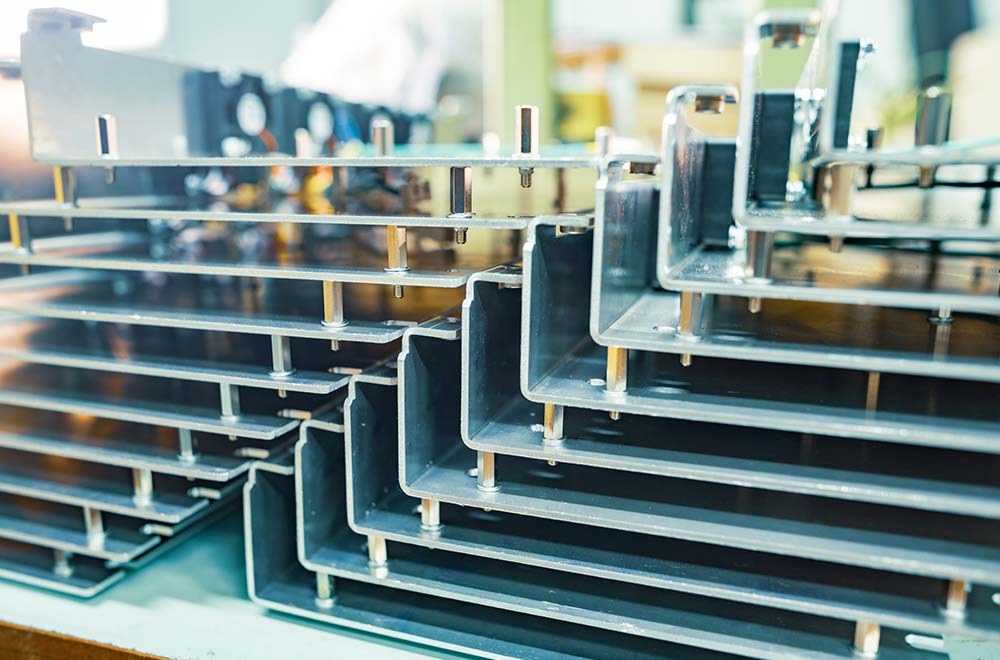

Structural Steel

This type of steel is commonly used in the construction industry. You can use it in the construction of buildings and other structures such as bridges, tunnels, etc. Structural steel contains approximately 2.1% carbon. To achieve high strength, you can increase the carbon content in this steel. However, doing so reduces the ductility of the steel.

In some applications, you need to consider the required amount of carbon. You must ensure that the carbon content meets the requirements of your project and certain specific standards.

Titanium

Titanium is a lightweight metal with strong corrosion resistance, making it a preferred choice for manufacturers. You can use this metal in medical projects involving joint replacement. Its ability to bond with bone makes it suitable for medical applications.