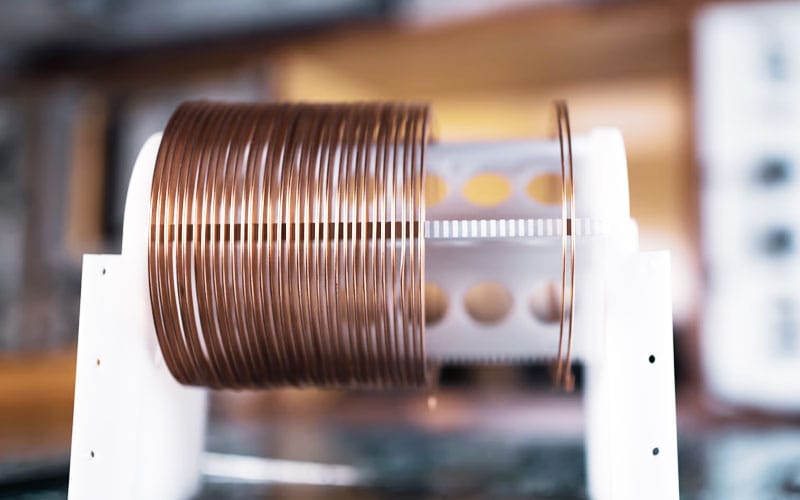

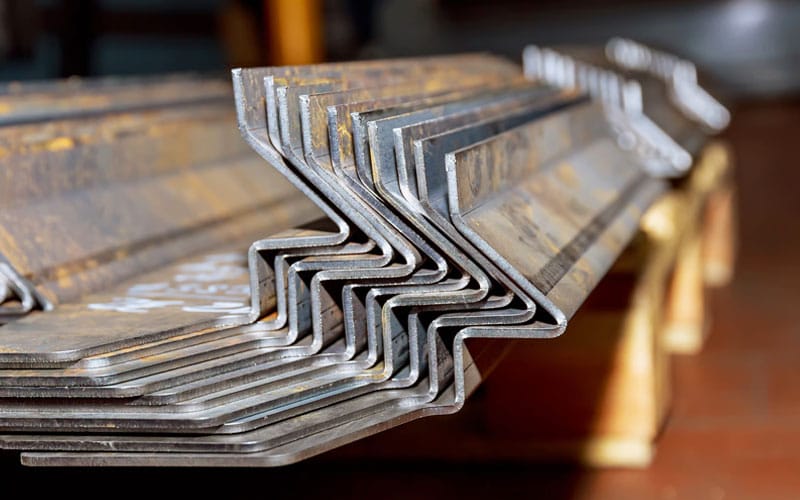

We provide precision metal stamping, sheet metal fabrication, CNC machining, and brazing services for aluminum, stainless steel, carbon steel, copper, and nickel alloys. Fast quotes, reliable quality, and on-time delivery.

One-stop metal product solutions, integrating custom development, precision manufacturing, and global delivery.

We are committed to building long-term partnerships through high consistency, high efficiency, and high responsiveness, becoming a reliable supplier for distributors, OEM/ODM brands, and global industrial buyers.

Nanpi Shuowei Metal Products Co., Ltd. and Cangzhou Lina Import & Export Co., Ltd. form a strong industrial-trade alliance rooted in the metal products sector. With seamless collaboration between precision manufacturing and international trade services, we deliver end-to-end metal product solutions for global customers—covering custom design support, tooling development, automated production, strict quality inspection, and worldwide logistics.

To become the globally preferred partner in the metal products and components sector , empowering diverse industries through precise metal solutions and building a future of sustainable, win-win cooperation.

We offer a complete range of metal processing services including stamping, sheet metal fabrication, CNC machining, and brazing. Whether you need prototype development or mass production, we provide tailored solutions.

Custom metal parts manufacturing with stable quality and scalable capacity.

High-efficiency stamping for precision parts and mass production.

Performing precise bending, forming, and hole punching on sheet metal structures.

Casting solutions for complex shapes and durable metal parts.

Precision machining for tight tolerances and functional accuracy.

Reliable brazing technology ensures strong and secure joints and a clean assembly.

Electrical components, heat dissipation parts, casters, housings

Medical components, sheet metal enclosures, industrial hardware

Structural parts, general industrial components

Forged parts, brackets, chassis, machinery components

High-temperature parts, chemical equipment components, critical industrial parts

By integrating automation, precision engineering, and data-based process optimization, we deliver metal products with higher accuracy, stronger performance, and better consistency.

Quality is the foundation of long-term cooperation. We implement a strict, ISO-compliant quality management system with 18 quality inspection points, ensuring every product meets international standards before delivery.

We provide end-to-end service support, covering technical consultation, production coordination, logistics arrangement, and after-sales assistance—ensuring smooth communication and efficient execution throughout the entire cooperation process.

Our Industry 4.0 smart factory and advanced automated production lines enable efficient, flexible, and scalable manufacturing—from prototyping to mass production—while maintaining consistent quality and stable lead times.

With a professional R&D team and multiple self-owned brands, we support OEM/ODM projects throughout the full product lifecycle—from concept design and prototyping to market-ready production.

With years of export experience, we understand international regulations, market standards, and customer expectations. Our products are supplied worldwide, helping partners compete effectively in their local markets.

With the perfect synergy of manufacturing and trade, we provide one-stop metal product solutions for customers around the world, covering customized research and development, precision production to cross-border delivery.

From raw material procurement, production management, order tracking to logistics and customs clearance, we maintain full control throughout the entire process.

Have other questions?

Yes. We provide full OEM/ODM services based on customer drawings, samples, or technical requirements. Our engineering team supports process optimization, tooling development, prototyping, and mass production.

We work with a wide range of materials including carbon steel, stainless steel, iron, copper, aluminum, and nickel-based alloys, suitable for different industries and working conditions.

Our capabilities cover stamping, sheet metal bending, casting, forging, machining, spring manufacturing, and brazing, enabling one-stop production for complex metal components.

We implement an ISO-compliant quality management system with 18 quality inspection points throughout the production process, ensuring stable quality and batch consistency.

Simply send us your drawings, samples, or requirements. Our team will review your project and provide a professional quotation and technical proposal promptly.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.

We are committed to sustainable manufacturing practices, including efficient material usage, waste reduction, and safe disposal of industrial waste. We strive to minimize environmental impact while maintaining high production standards.