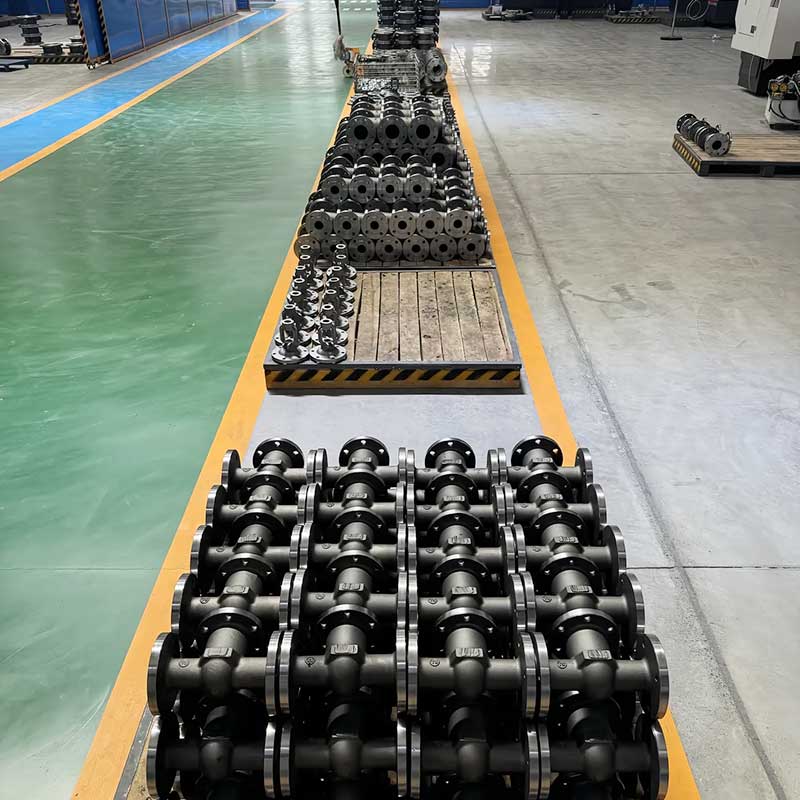

A valve is a fluid control component manufactured through valve body molding, valve core assembly, and drive mechanism combination. Its core functions are to control the flow of fluid (liquid, gas, or slurry) in pipes or equipment, regulate flow rate, and control pressure.

A valve is a fluid control component manufactured through valve body molding, valve core assembly, and drive mechanism combination. Its core functions are to control the flow of fluid (liquid, gas, or slurry) in pipes or equipment, regulate flow rate and pressure, and provide protective functions such as sealing, backflow prevention, and explosion protection. The valve body, valve cover, operating handle, and other components can be processed through metal stamping, bending, and welding processes, supporting full-dimensional non-standard customization.

It is widely used in industrial fields such as petrochemicals, new energy, water treatment, and engineering machinery.

Applicable Scenarios

1. Petrochemical / Natural Gas Field

Applicable Products: Pneumatic explosion-proof ball valves, electric gate valves, check valves

Application Areas: Crude oil/natural gas transmission pipelines, reactor inlets and outlets, storage tank outlets

Core Function: Withstands high pressure (PN≤100bar), high temperature (≤400℃), and highly corrosive media, ensuring safe fluid transportation and preventing leaks that could cause safety accidents.

2. New Energy Field (Energy Storage / Photovoltaics / Hydrogen Energy)

Applicable Products: Aluminum alloy lightweight ball valves, electric butterfly valves, check valves

Application Areas: Energy storage container cooling pipelines, photovoltaic cleaning water pipelines, hydrogen energy storage tank inlets and outlets

Core Function: Lightweight design reduces equipment weight, withstands high and low temperatures (-40℃~120℃), and meets the long-term stable operation requirements of new energy equipment.

3. Water Treatment / Environmental Engineering

Applicable Products: Stainless steel butterfly valves, manual gate valves, check valves

Application Areas: Sewage treatment plant pipelines, water purification equipment filtration systems, exhaust gas treatment tower spray pipelines

Core Function: Resistant to acid and alkali corrosion, excellent sealing performance, prevents sewage/wastewater leakage, and meets the stringent standards of environmental engineering.

4. Construction Machinery / Hydraulic Systems

Applicable Products: High-pressure hydraulic valves, stamped lightweight ball valves, check valves

Application Areas: Excavator hydraulic pipelines, loader hydraulic systems, air compressor storage tanks

Core Function: Withstands the impact load of high-pressure hydraulic oil, fast response speed, ensuring precise control of construction machinery movements.

5. HVAC / Building Water Supply and Drainage

Applicable Products: Manual gate valves, electric control valves, check valves

Application Areas: Building heating pipelines, central air conditioning water circulation systems, tap water transmission pipelines

Core Function: Regulates flow and temperature, prevents water backflow, and ensures stable heating and water supply in buildings.

6. Food and Pharmaceutical Field

Applicable Products: Food-grade stainless steel ball valves, sanitary butterfly valves

Application Areas: Food and beverage production lines, pharmaceutical preparation transmission pipelines

Core Function: Complies with FDA standards. Hygienic standards are met, with a smooth, polished surface free of crevices to prevent bacterial growth and ensure the hygiene and safety of the product.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

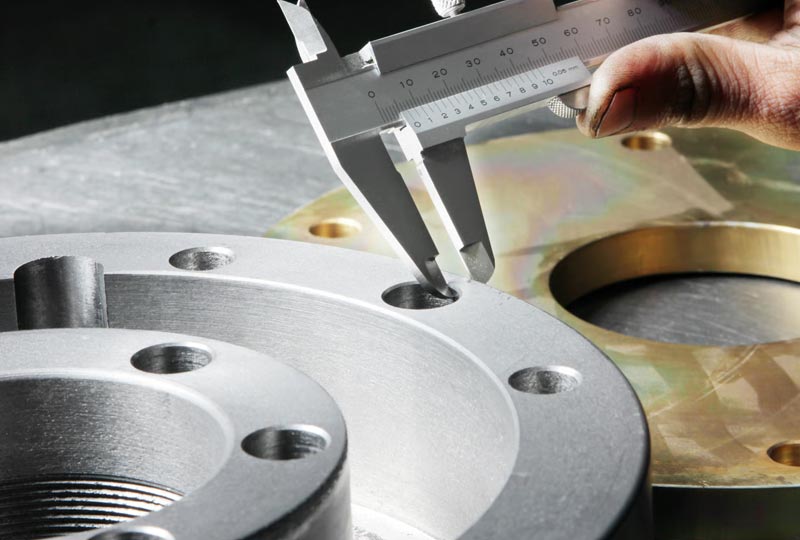

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.