We support full-dimensional non-standard customization, allowing for adjustments to wire diameter, number of turns, free length, and elastic parameters based on customer equipment and operating conditions. This is a core supporting product category for hardware stamping export businesses.

Springs are fundamental hardware components that utilize elastic deformation to achieve energy storage, restoration, buffering, shock absorption, and clamping functions. They are formed through precision stamping, bending, and heat treatment processes and are widely used in sheet metal structures and assembly equipment in fields such as electrical cabinets, new energy equipment, construction machinery, and rail transit.

We support full-dimensional non-standard customization, allowing adjustment of wire diameter, number of turns, free length, and elastic parameters according to customer equipment operating conditions. Springs are a core product category in our hardware stamping export business. Non-standard customization is supported.

Applicable Scenarios

1. Electrical Cabinets / Sheet Metal Enclosures

Suitable Products: Compression Springs, Torsion Springs, Retaining Rings

Application Areas: Cabinet door hinges (torsion springs provide automatic return), circuit breaker contacts (compression springs ensure tight contact), drawer slides (retaining rings for positioning)

Core Function: Compensate for assembly deviations, buffer equipment operating vibrations, and ensure the stability of electrical connections.

2. New Energy Equipment (Battery Packs / Charging Piles)

Suitable Products: Compression Springs, Wave Springs, Shaped Leaf Springs

Application Areas: Battery module compression (compression springs provide uniform pre-tightening force), charging pile plug contacts (shaped springs ensure smooth insertion and removal), energy storage container door locks (tension springs for resetting)

Core Function: Withstands high and low temperatures (-40℃~120℃), strong fatigue resistance, meeting the long-life requirements of new energy equipment.

3. Construction Machinery / Rail Transit

Suitable Products: Heavy-duty Compression Springs, Torsion Springs, Spiral Springs

Application Areas: Excavator maintenance door latches (torsion springs for locking), high-speed train door locking mechanisms (spiral springs for energy storage), truck compartment shock absorbers (heavy-duty compression springs for cushioning)

Core Function: Withstands heavy loads and high-frequency vibrations, impact-resistant, corrosion-resistant, and adaptable to harsh outdoor working conditions.

4. Precision Instruments / Medical Devices

Suitable Products: Miniature Compression Springs, Extension Springs, Phosphor Bronze Springs

Application Areas: Instrument switches (miniature springs trigger signals), medical equipment clamps (extension springs for clamping), testing equipment probes (compression springs ensure contact)

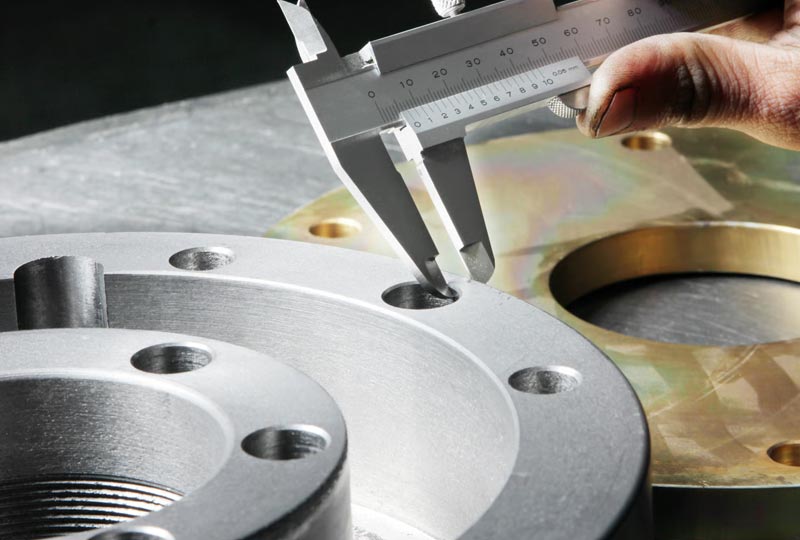

Core Function: High dimensional accuracy (±0.01mm), stable elastic parameters, and no magnetic interference.

5. Automotive Sheet Metal Parts

Suitable Products: Torsion Springs, Shaped Springs, Retaining Rings

Application Areas: Car trunk hinges (torsion springs for support), car door limiters (shaped springs for cushioning), sheet metal buckles (retaining rings for fixing)

Core Function: Complies with automotive industry standards, salt spray resistant, anti-aging, and adaptable to the vibration environment of the entire vehicle.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.