Signage is a functional accessory that combines information display, safety warnings, and brand presentation. Text, patterns, and parameters are permanently applied to various substrate surfaces through processes such as stamping, etching, and screen printing.

Nameplates are functional accessories that combine information identification, safety warnings, and brand display functions. Through processes such as stamping, etching, and screen printing, text, patterns, and parameters are permanently applied to the surface of various base materials. They are widely used in industrial equipment, electrical cabinets, new energy products, and rail transit systems.

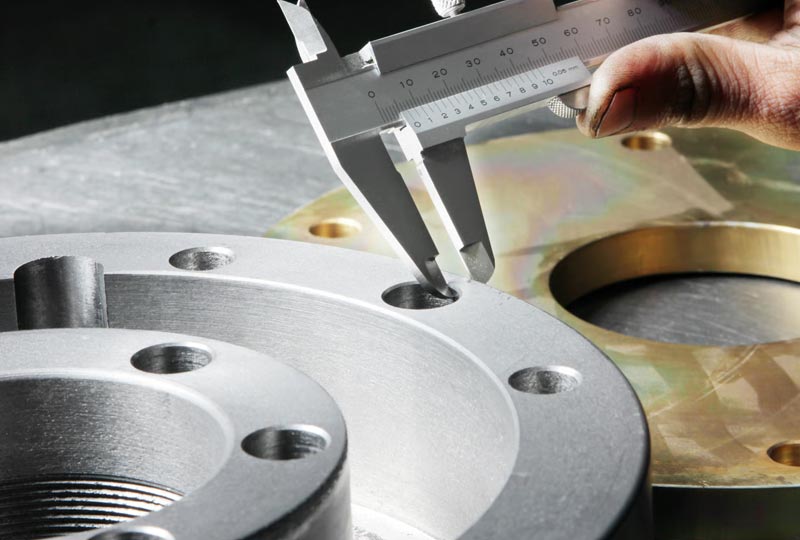

Based on our expertise in metal stamping and sheet metal processing, custom metal nameplates are our core product type. We also provide complementary non-metallic nameplate solutions, supporting full-process non-standard customization to meet the diverse needs of overseas customers regarding size, material, performance, and compliance.

Applicable Scenarios

1. Electrical Equipment / Sheet Metal Enclosures: Parameter labels for power distribution cabinets, inverters, and charging stations (indicating voltage, current, and power), warning labels (for electric shock and high temperature), and brand labels.

2. New Energy Sector: Model labels, production date labels, and traceability QR code labels for battery packs and energy storage containers; power identification labels for photovoltaic modules.

3. Rail Transit / Automotive: Route indicator labels for subway cars, component identification labels for car engine compartments, and operation warning labels for construction machinery.

4. Industrial Machinery and Equipment: Nameplates and maintenance reminder labels for machine tools, air compressors, and pumps and valves, featuring wear resistance and oil resistance.

5. Construction / Security: Warning labels for building fire safety facilities, and status indicator labels for security equipment, with strong weather resistance for long-term outdoor use.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.