The mouse cage is a reusable mechanical mouse trap. Its core structural components (cage body, trigger pedal, spring door, and locking mechanism) are manufactured using metal stamping, bending, spot welding, and assembly processes, resulting in a sturdy, durable, and deformation-resistant structure.

The mouse cage is a reusable mechanical mouse trap. Its core structural components (cage body, trigger pedal, spring door, and locking mechanism) are manufactured using metal stamping, bending, spot welding, and assembly processes, resulting in a sturdy, durable, and deformation-resistant structure.

The product uses bait to trigger a pedal-activated door locking mechanism. When a mouse enters the cage and touches the pedal, the cage door automatically closes, achieving non-toxic, pollution-free, and humane capture while preventing accidental harm to other animals.

The mouse cage is widely used in various rodent control scenarios, including warehousing and logistics, food processing plants, restaurants, agricultural facilities, homes, and public buildings. It is suitable for both indoor and outdoor environments.

This product supports multi-size and structural customization. Materials and specifications can be optimized based on customer requirements for target animals, placement space, corrosion resistance, and operating environment.

Typical Applications:

• Warehousing and Logistics: Rodent control in warehouses, sorting centers, and cold chain storage facilities.

• Food Processing and Catering: Environmental protection in food factories, central kitchens, and restaurant kitchens.

• Agriculture and Animal Husbandry: Rodent control around granaries, feed rooms, greenhouses, and livestock farms.

• Commercial Buildings: Public places such as shopping malls, hotels, schools, hospitals, and office buildings.

• Residential Environments: Home garages, storage rooms, basements, and yards.

• Municipal and Public Facilities: Waste transfer stations, underground pipeline entrances, and equipment rooms.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

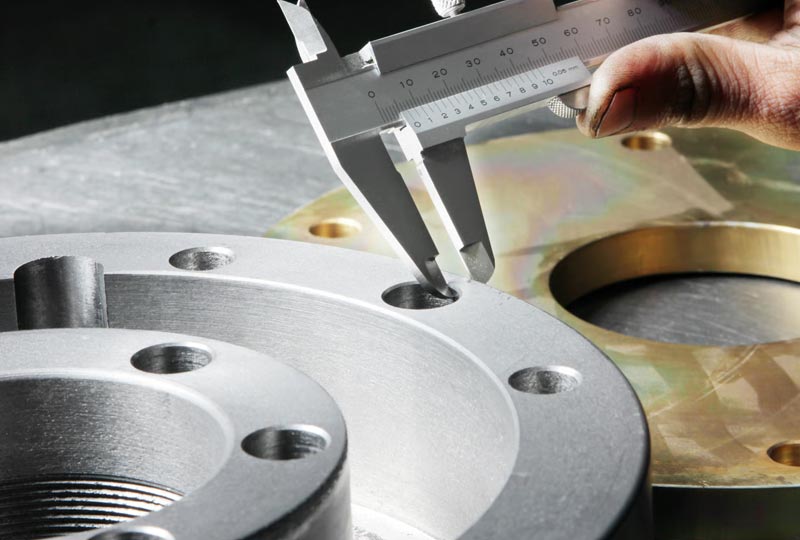

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.