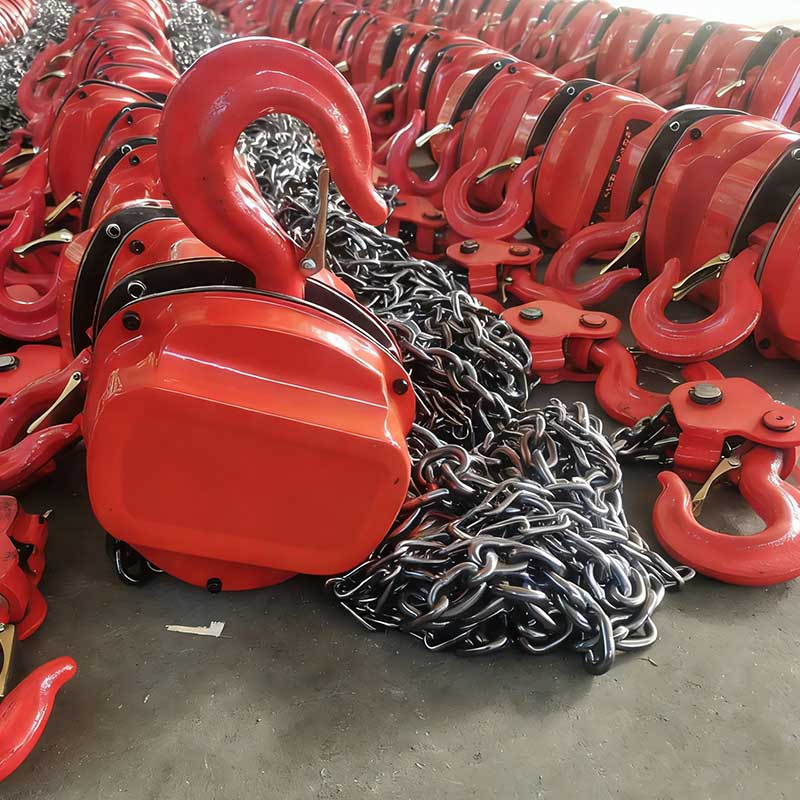

A lifting tool driven by a manually operated chain, which uses gear transmission to lift heavy objects. It features a compact structure, simple operation, strong load capacity, and requires no power source. It is widely used in warehousing, construction sites, maintenance, and equipment installation scenarios.

A hand chain hoist is a portable lifting device powered by human effort. Its core structural components (housing, gear set, sprocket, hook, and support base) are manufactured using high-strength metal casting, forging, precision machining, and assembly processes, ensuring a stable overall structure, reliable transmission, and strong load-bearing capacity. The device uses a chain-driven gear transmission system to achieve smooth lifting and lowering of heavy objects.

The hand chain hoist is equipped with a reliable ratchet brake and safety locking mechanism, which automatically maintains its position under load, preventing accidental slippage or uncontrolled falling and ensuring operational safety.

This product is widely used in warehousing and logistics, construction, equipment installation, factory maintenance, power engineering, shipping ports, and confined space operations, and is suitable for environments without power supply or for mobile operations.

The hand chain hoist supports customization of various load capacities. Structural and material configurations can be optimized according to customer requirements for lifting capacity, lifting height, and operating environment (indoor/outdoor/corrosive environment).

Typical Applications:

• Warehousing and logistics: Lifting, loading, unloading, and short-distance transportation of goods.

• Construction sites: Steel structure installation, equipment positioning, and small lifting operations.

• Factory workshops: Mold replacement, equipment maintenance, and auxiliary lifting on production lines.

• Power and equipment installation: Positioning and lifting of transformers, cabinets, and pipe components.

• Ships and ports: Deck equipment maintenance and lifting of small components.

• Mining and maintenance scenarios: Lifting and pulling heavy objects in confined spaces.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

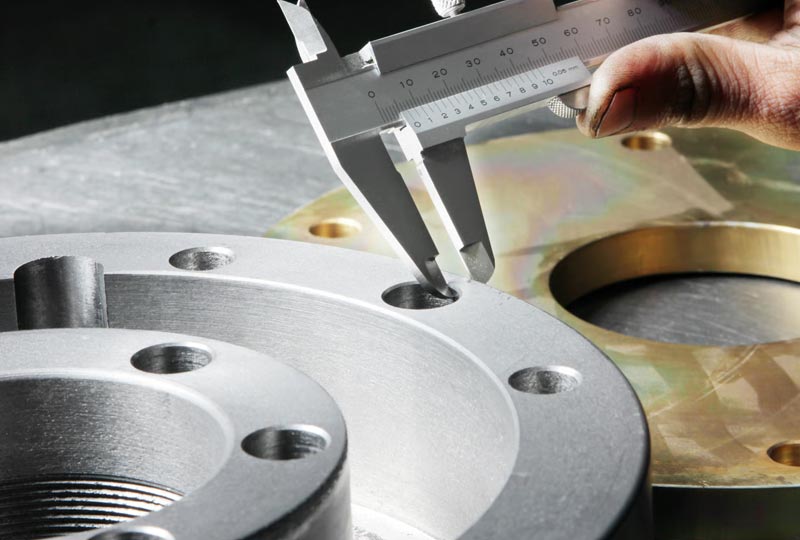

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.