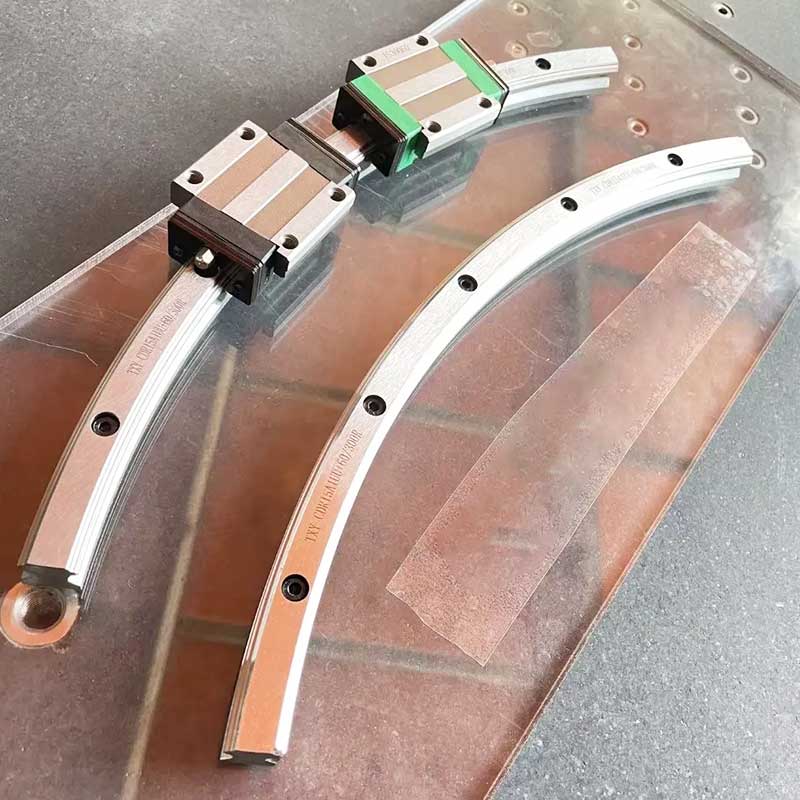

Guide rails are linear guiding components manufactured through precision rolling or machining processes. Their core function is to provide a stable linear motion trajectory for the moving parts of equipment, while also bearing loads, providing limits, and absorbing shocks.

Guide rails are linear guiding components manufactured through precision rolling or machining processes. Their core function is to provide a stable linear motion trajectory for the moving parts of equipment, while also bearing loads, providing limits, and absorbing shocks.

They are widely used in sheet metal structures for electrical cabinets, industrial equipment, new energy enclosures, and rail transit systems.

We support full-dimensional non-standard customization, allowing for adjustments to structure and dimensions based on customer installation space, load-bearing requirements, and motion precision. They are a core component category for hardware stamping/sheet metal export businesses.

Applicable Scenarios

1. Electrical Cabinets / Sheet Metal Enclosures

Compatible Products: Drawer slides, linear guides

Application Areas: Distribution cabinet drawers, server chassis trays, PLC control cabinet maintenance doors

Core Function: Ensures smooth and precise movement of drawers/trays, provides accurate positioning, and supports the weight of equipment components, suitable for high-frequency operation scenarios in industrial workshops.

2. New Energy Equipment (Battery Packs / Energy Storage Containers)

Compatible Products: Heavy-duty slides, stainless steel guide rails

Application Areas: Battery module pull-out racks, energy storage container maintenance doors, charging pile internal component slides

Core Function: Withstands high and low temperatures (-40℃~120℃), corrosion-resistant, supports quick disassembly and maintenance of battery modules, meeting the long-life requirements of new energy equipment.

3. Construction Machinery / Rail Transit

Compatible Products: Heavy-duty slides, slides with locking mechanisms

Application Areas: Excavator cab door slides, high-speed rail on-board equipment box maintenance doors, engineering vehicle toolbox slides

Core Function: Withstands heavy loads and high-frequency vibrations, locking mechanism prevents component displacement during vehicle operation, adaptable to harsh outdoor working conditions.

4. Precision Instruments / Medical Devices

Compatible Products: Aluminum alloy linear guides, miniature guide rails

Application Areas: Medical testing equipment sample stage slides, precision instrument lens adjustment guides, laboratory equipment drawers

Core Function: High motion accuracy, lightweight, no magnetic interference, suitable for fine-tuning and positioning requirements of high-precision equipment.

5. Warehousing and Logistics Equipment

Compatible Products: Cold-rolled steel slides, roller-type linear guides

Application Areas: Lightweight shelving pull-out shelves, logistics turnover box guide rails, automated sorting equipment slides

Core Function: Cost-effective, stable load-bearing capacity, supports rapid access to goods, suitable for large-scale applications in warehousing scenarios.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

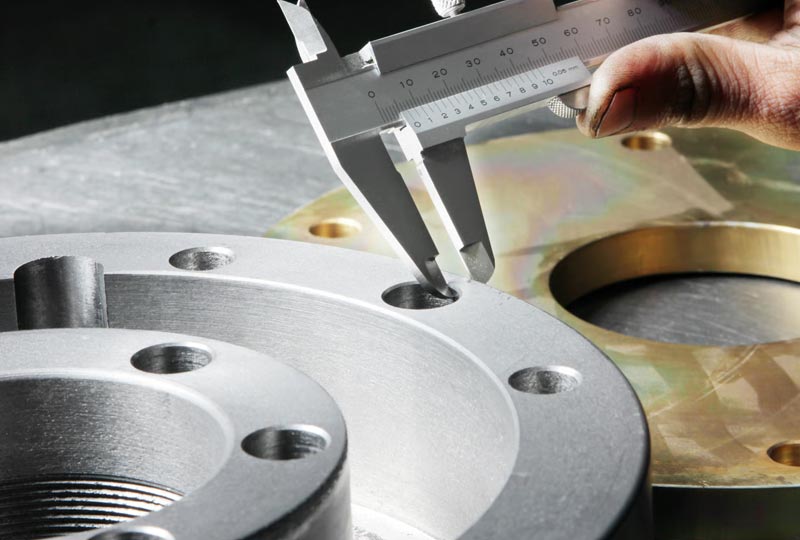

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.