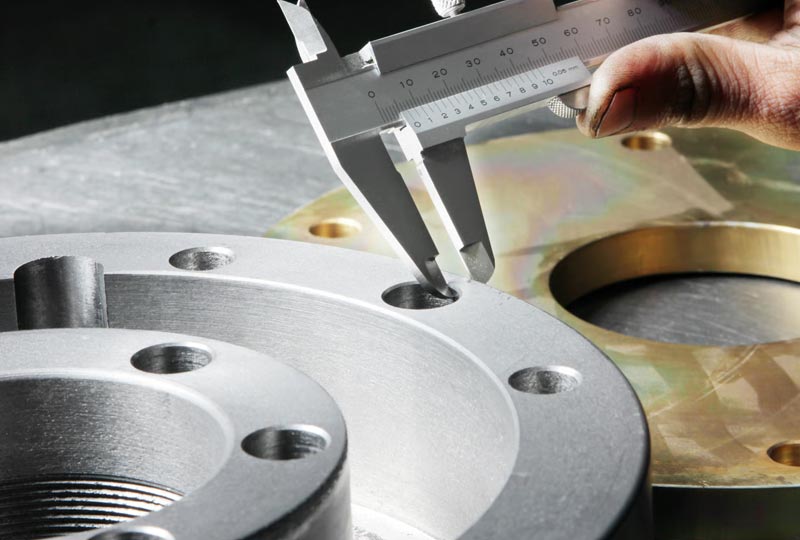

A flange is a disc-shaped connecting component manufactured through precision stamping, forging, and machining processes. Its core function is to provide a detachable, rigid connection between pipes, valves, pressure vessels, and equipment bodies.

A flange is a disc-shaped connecting component manufactured through precision stamping, forging, and machining processes. Its core function is to provide a detachable, rigid connection between pipes, valves, pressure vessels, and equipment bodies, while also providing sealing, load-bearing, pressure resistance, and vibration resistance.

Flanges can be supplied in conjunction with metal stamping/sheet metal parts (such as pipe supports and equipment housings), supporting full-dimensional non-standard customization, and are widely used in industrial fields such as petrochemicals, new energy, water treatment, and engineering machinery.

Applicable Scenarios

1. Petrochemical / Natural Gas Pipeline Systems

Applicable Products: Forged Weld Neck Flanges, Stainless Steel Flanges

Application Areas: Pipeline connections for transporting crude oil, natural gas, and chemical media

Core Function: Withstands high pressure (≤100 bar), high temperature (≤600℃), and highly corrosive media, ensuring leak-free pipeline sealing.

2. New Energy Equipment (Energy Storage / Photovoltaic / Hydrogen Energy)

Applicable Products: Aluminum Alloy Stamped Flanges, Stainless Steel Blind Flanges

Application Areas: Energy storage container pipeline interfaces, photovoltaic cooling system connections, hydrogen energy storage tank inlets and outlets

Core Function: Lightweight design reduces equipment weight, withstands high and low temperatures (-40℃~120℃), and meets the long-term operation requirements of new energy equipment.

3. Water Treatment / Environmental Engineering

Applicable Products: 304 Stainless Steel Stamped Flanges, Plastic Composite Flanges

Application Areas: Sewage treatment pipelines, water purification equipment, exhaust gas treatment tower interfaces

Core Function: Resistant to acid and alkali corrosion, good sealing performance, preventing secondary pollution caused by sewage/exhaust gas leakage.

4. Construction Machinery / Pressure Vessels

Applicable Products: Carbon Steel Forged Flanges, Non-standard Shaped Flanges

Application Areas: Excavator hydraulic pipelines, air compressor storage tanks, pressure vessel inlets and outlets

Core Function: Withstands equipment operating vibrations and impact loads, and the detachable design facilitates subsequent maintenance and repair.

5. Marine / Offshore Engineering

Applicable Products: 316L Stainless Steel Flanges, Marine Forged Flanges

Application Areas: Ship power system pipelines, offshore platform equipment connections

Core Function: Withstands high salt spray corrosive environments, meets classification society certification standards, and ensures the safe operation of offshore equipment.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.