Copper flexible connectors and flexible copper busbars are types of flexible conductive connecting components. Their core function is to provide flexible conductive connections between rigid components in electrical systems, ensuring stable transmission of high currents.

Copper flexible connectors and flexible copper busbars are flexible conductive connection components. Their core function is to provide flexible conductive connections between rigid components in electrical systems, compensating for installation deviations, absorbing vibration displacement, reducing electromagnetic interference, and ensuring stable transmission of high currents.

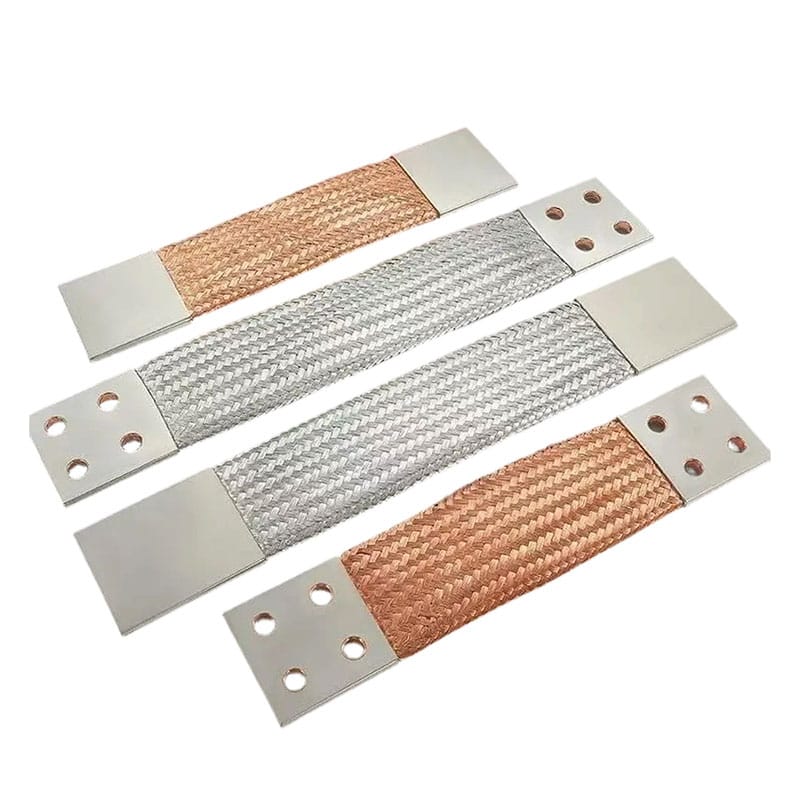

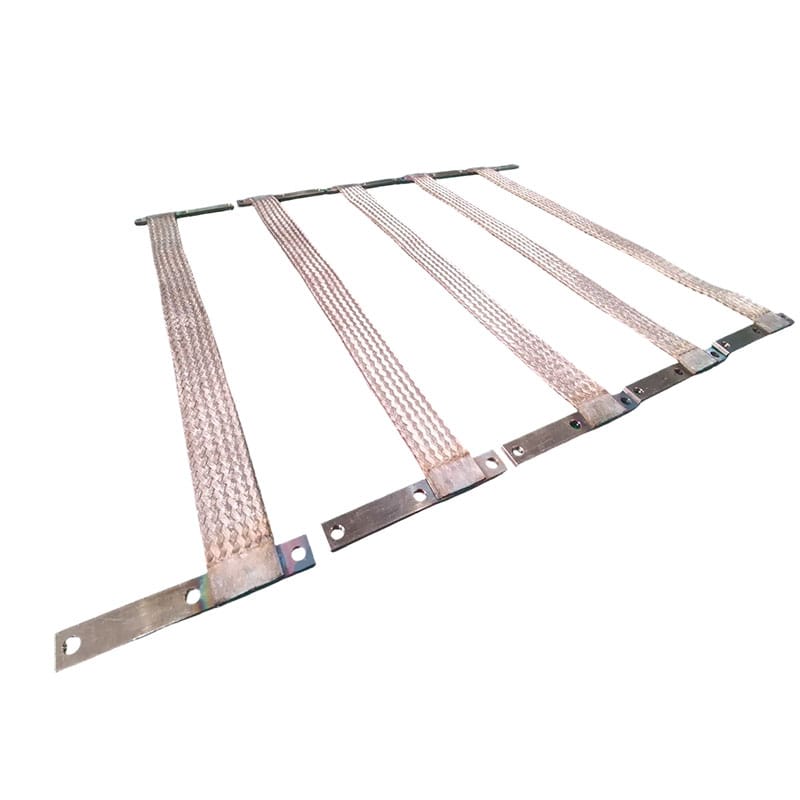

These four types of products, due to differences in material (copper/aluminum) and structural form, are suitable for different current, working conditions, and cost requirements. They are core supporting components in new energy, power, and rail transit fields, and all support non-standard customization. They are made of multi-layered high-purity copper foil (T2/TU1 oxygen-free copper), formed by high-temperature vacuum welding (diffusion welding/ultrasonic welding). The ends can be stamped into different specifications of connecting terminals (such as flat type, hole type), and the surface can be tin-plated or silver-plated to enhance corrosion resistance and conductivity; some products have built-in insulation sleeves (such as silicone rubber, fluoroplastics) to improve safety protection.

Aluminum flexible connectors and flexible aluminum busbars are made of multi-layered high-purity aluminum foil (1060/1070 pure aluminum), formed by ultrasonic welding or argon arc welding. The ends can be stamped into flat terminals suitable for bolt connection, and the surface can be anodized or tin-plated to improve corrosion resistance; compared with copper flexible connectors, they are lighter and less expensive.

Applicable Scenarios

1. New Energy Battery Packs: Connecting power battery modules to busbars, and battery packs to inverters; compensating for displacement caused by thermal expansion and contraction of the battery pack; and cushioning vibrations during vehicle operation.

High/Low Voltage Distribution Cabinets/Switchgear: Flexible connection of busbars to circuit breakers and disconnectors, addressing cabinet installation deviations and reducing the risk of hard connection failures.

2. Transformers/Rectifiers: Connecting the output terminals of high-voltage equipment to external cables, absorbing vibrations during equipment operation, and reducing electromagnetic noise.

3. Metallurgical Electric Furnaces: Connecting high-current electric furnace electrodes to busbars, withstanding high-temperature environments and meeting the requirements for short-term ultra-high current transmission.

4. Low-Voltage Switchgear: Branch connections for distribution boxes and busbar systems, replacing traditional cables and reducing overall equipment weight and cost.

5. Photovoltaic Bracket Grounding System: Cross-bonding grounding of photovoltaic module metal brackets, achieving equipotential connection and ensuring lightning protection safety.

6. Automotive Lightweight Components: Low-voltage circuit connections for battery packs in new energy commercial vehicles and buses, meeting the lightweight design requirements of the entire vehicle.

7. Building Electrical Grounding: Grounding cross-bonding of steel structures and metal components in high-rise buildings, resistant to humid outdoor environments and less prone to rust.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

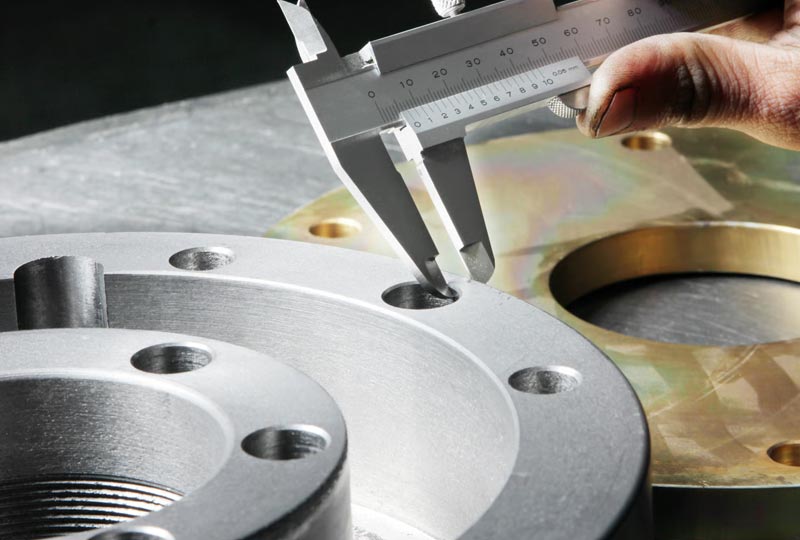

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.