Agricultural machinery and tools are agricultural production equipment and accessories manufactured using precision stamping, sheet metal bending, welding assembly, and heat treatment processes. They cover all stages of agricultural production, including tillage, planting, management, harvesting, storage, and transportation.

Agricultural machinery and tools are agricultural production equipment and accessories manufactured using precision stamping, sheet metal bending, welding assembly, and heat treatment processes. They cover all stages of agricultural production, including tillage, planting, management, harvesting, storage, and transportation. Their core function is to replace manual labor, improve agricultural production efficiency, and ensure crop yield and quality.

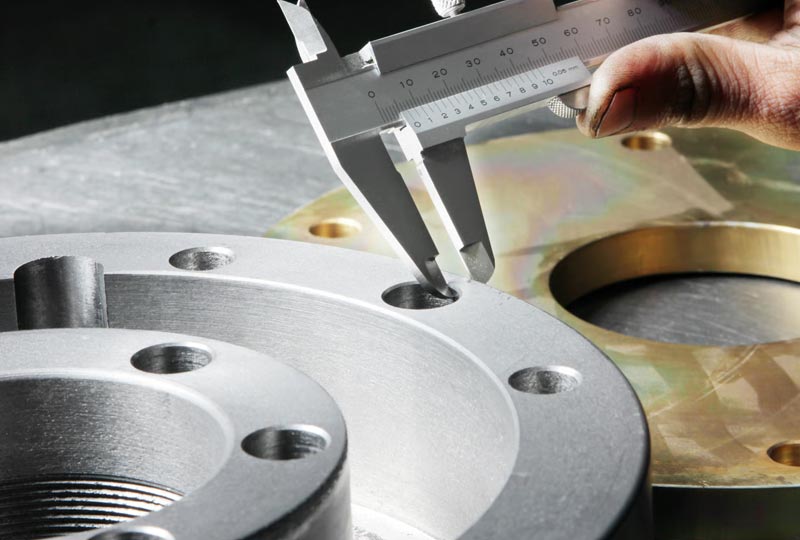

The products use carbon steel, stainless steel, and high-strength aluminum alloys as core base materials, and the metal structural parts are mostly formed through metal stamping/sheet metal processes. They support comprehensive non-standard customization based on different regional farmland conditions and crop types overseas.

They are widely applicable to various scenarios worldwide, including large-scale field cultivation, orchard farming, and livestock breeding.

Applicable Scenarios

1. Large-scale Field Crop Planting (Global mainstream demand)

Applicable products: Rotary tillers, precision seeders, combine harvesters and related accessories; Applicable crops: Wheat, corn, rice, soybeans; Core function: Achieving full mechanization from tillage and sowing to harvesting. Stamped/sheet metal parts ensure the stability of equipment during high-frequency operation in large-area farmland, improving production efficiency and reducing labor costs.

2. Orchard/Cash Crop Scenarios (High-end overseas demand)

Applicable products: Small pruning machines, backpack sprayers, fruit tree fertilizer applicators; Applicable crops: Citrus, grapes, olives, nuts; Core function: Small-scale customized agricultural tools are adapted to the confined spaces of orchards. Stainless steel stamped parts prevent corrosion from pesticides. Precise pruning and fertilization ensure crop quality, adapting to orchard planting models in Europe, America, and Southeast Asia.

3. Livestock Farming Support Scenarios

Applicable products: Feed grinders, straw shredders, forage conveyor chains; Applicable scenarios: Dairy farms, beef cattle farms, poultry farms; Core function: Wear-resistant stamped blades efficiently process feed, and sheet metal conveyor troughs ensure clean feed transportation, meeting the feed processing needs of large-scale farming and reducing breeding costs.

4. Small-scale Overseas Farmer Scenarios

Applicable products: Manual/small electric weeders, simple threshing machines, portable sprayers; Applicable regions: Small-scale farmland in Africa and Southeast Asia; Core function: Lightweight design facilitates transportation, simple structure is easy to maintain, and stamped parts are inexpensive, adapting to farmers’ limited budgets while meeting basic operational needs.

5. Specialty Crop Planting Scenarios

Applicable products: Sugarcane harvester accessories, cotton picker screens, potato planters; Applicable crops: Sugarcane, cotton, potatoes, sugar beets; Core function: Customized stamped/sheet metal parts are adapted to the growth characteristics of specialty crops, such as sugarcane-specific cutting blades and potato damage-preventing conveyor chains, ensuring the quality of special crop harvesting.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.