We provide high-precision stamping, sheet metal fabrication, machining, and assembly services for electronic and electrical components — including connectors, heat sinks, housings, and precision brackets. Our production is suitable for both small batch prototypes and large-scale mass production.

We are committed to providing the highest quality precision metal parts manufacturing services, including precision casting, investment casting, sand casting, and CNC machining. We offer customized solutions, and before mass production, we will provide a free sample for your testing and confirmation.

Features: Investment casting has high precision, can adapt to complex shapes, has smooth surface and little material waste.

Applications: Aerospace, precision machinery, automobiles, medical equipment, etc.

Features: Uses sand mold, which is low in cost and suitable for large and complex-shaped metal castings.

Applications: Automotive parts, mechanical structural parts, large castings.

Features: High precision, complex parts, and mass production.

Applications: Molds, medical device parts, aluminum alloy engine cylinder blocks/cylinder heads.

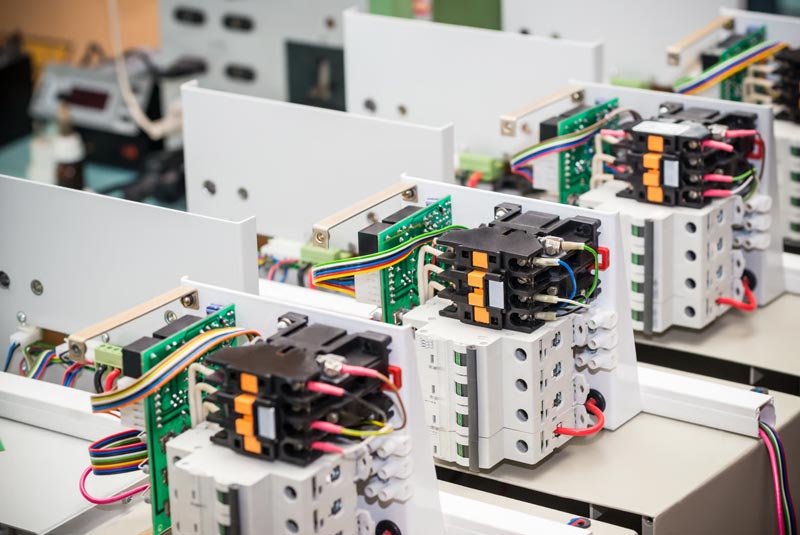

Electronic Device Enclosures: Communication module enclosures, control unit enclosures, sensor enclosures, etc.

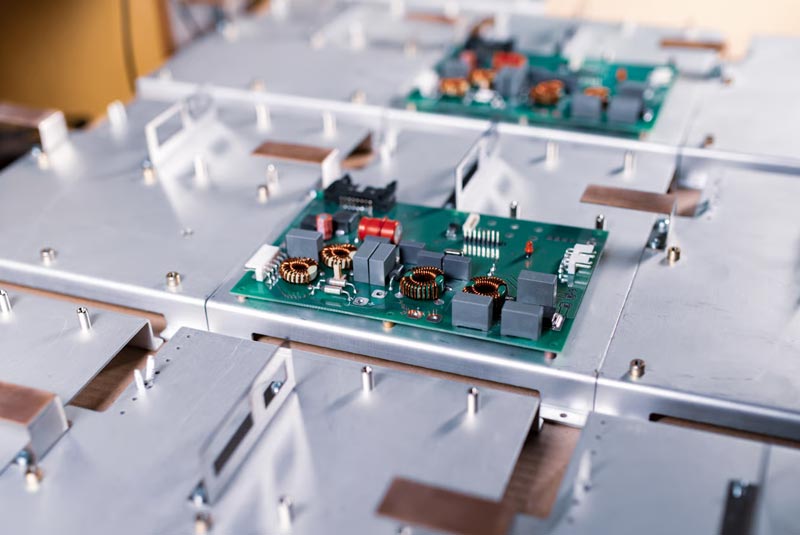

Thermal Management Components: Power module heat sinks, LED heat sinks, electronic chassis thermal pads, etc.

Support and Connector Components: Shielding covers, brackets, grounding frames, mounting bases, etc.

Small Precision Components: Socket bases, sensor module housings, etc.

Used for conductive components and connectors, possessing excellent conductivity and solderability.

Used for heat sinks, casings, and brackets, offering lightweight properties and good thermal conductivity.

Used for structural support components and housings, providing corrosion resistance, wear resistance, and high stability.

Used for critical components in high-temperature or highly corrosive environments.