Casting is the process of transferring molten metal into a mold, allowing it to cool and harden to form the desired shape. Furthermore, this process is ideal for mass-producing parts, as the molds can be reused to produce similar products. Casting comes in various forms, including die casting, semi-permanent mold casting, and permanent mold casting.

Die casting is the process of forcing liquid metal into a steel mold. The mold is the die. In die casting, you place the injected metal under high pressure and hold it in place to harden. This process is ideal for high-speed applications.

Semi-permanent mold casting features expandable cores, which makes them less expensive to remove and easier to manage. With permanent mold casting, metal parts manufacturers can produce stronger castings than when using die casting. However, removing them from the final product can be difficult.

There is also sand casting. With this process, you can cast by pressing a specific pattern into a sand mixture. This creates a mold into which you pour molten metal. This is a slow process but is less expensive compared to other types of casting. Additionally, it is useful when dealing with complex designs.

Cutting

This is one of the most common metalworking methods. It involves dividing a metal workpiece into smaller pieces. While the oldest method of cutting is sawing, modern cutting methods include power shears, waterjet cutting, laser cutting, etc.

Cutting can be done in various ways, including using power tools, hand tools, and CNC cutting machines. Sometimes, cutting may be the initial stage of manufacturing, or it may be the only process.

Another type of cutting is die cutting. This cutting process utilizes a die to cut the metal. The die is a specially designed tool with sharp edges. Rotary die cutting uses a rotating die to cut the material as it is fed into a press.

Punching

Punch presses have well-shaped turrets that help strike the metal through a die, creating holes. Regardless of the final product, it may be a perforated metal piece that helps with fastening. You can achieve smaller punches manually, while most punch presses are mechanical. Furthermore, CNC punch presses have become common and are suitable for both light and heavy metal fabrication.

Folding

Folding is a metalworking process that allows you to manipulate metal to bend at specific angles. Bending machines are the most commonly used because they compress the metal to create a bend. Additionally, you place the workpiece between a die and a punch, and the punch applies pressure to create the bend.

This process helps in shaping metal sheets. Furthermore, you can achieve folding by striking the workpiece until it bends. You can also use a folding machine. This machine features a front panel that lifts upwards. This causes the extended metal to bend, a flat metal surface where you can place the sheet, and a clamp that ensures the workpiece stays in place.

Welding

Welding allows at least two pieces of metal to be joined together through a combination of pressure and heat. This process is well-known because the individual components can be of any size, form, or shape. Some well-known welding procedures include MIG welding, arc or stick welding, flux-cored arc welding, and tungsten inert gas (TIG) welding.

Forging

Like cutting, forging is one of the oldest metalworking techniques.

To this day, forging remains a reliable method and is still used to shape metal into different sizes. Furthermore, there are different types of forging. These include open-die forging, hot forging, and cold forging. While each method has its unique characteristics, they are all similar in utilizing compressive force to press, bend, or shape the metal to form the desired shape.

Extrusion

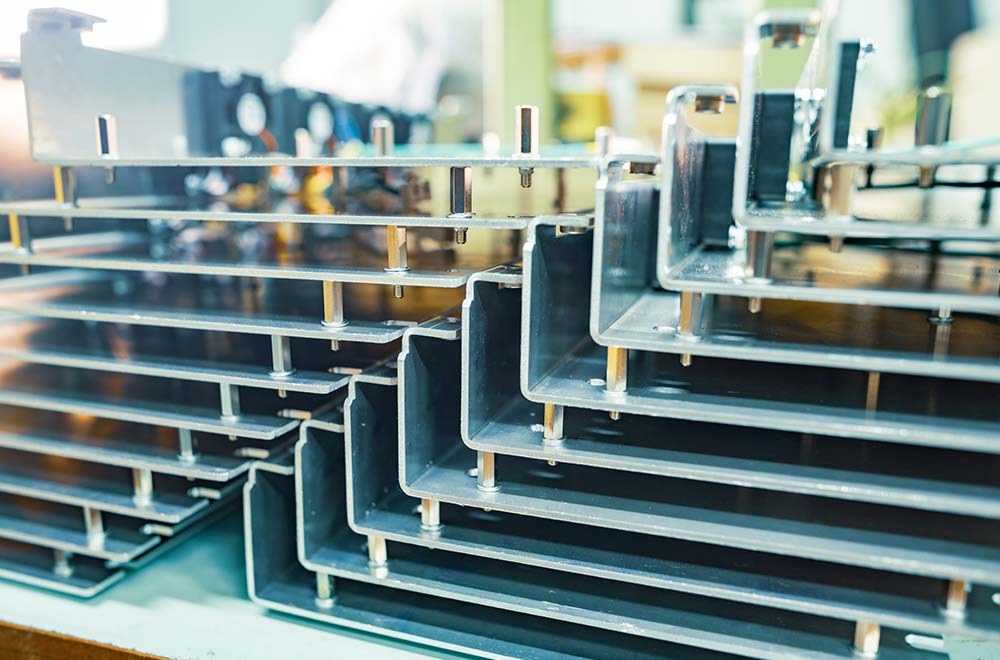

The extrusion process is not limited to metals, as it can also be used to manufacture polymer and plastic products. Additionally, the extrusion process can be used to manufacture sectional components or aluminum or steel beams.

In the extrusion process, a solid billet made of metal or alloy is passed through a die with a unique cross-section. You can achieve this using a high-pressure and high-power hydraulic system, which allows the die to shape the billet. After extruding the product, you can immediately perform post-processing measures to eliminate defects, improve its appearance, and make some adjustments.

Aluminum extrusions are the most common application of extruded profiles. They can be used to manufacture door and window frames, mullions, railings, etc. Although aluminum does not corrode, manufacturers usually add an extra powder coating to the material. This makes it more aesthetically pleasing and extends its lifespan.

Machining

Machining is another metal fabrication method that involves removing material from a workpiece to shape it. You can perform this process in different ways. Machining offers different processes. Let’s consider them.

Drilling

This process uses a drill bit to create holes in a material. These drill bits are typically pressed against the material and rotated rapidly to form a circular hole.

Metal Stamping

This process is particularly suitable for sheet metals such as aluminum, brass/copper, and stainless steel. You can also combine this procedure with other manufacturing methods to achieve the desired results.

An important application of stamping technology is in the assembly and manufacturing of automotive parts. Furthermore, this method helps in designing vehicle components, including wheel covers, firewalls, trunk lids, etc.

Another reason why stamping technology is ideal for automobiles is its ability to create customized and unique designs.