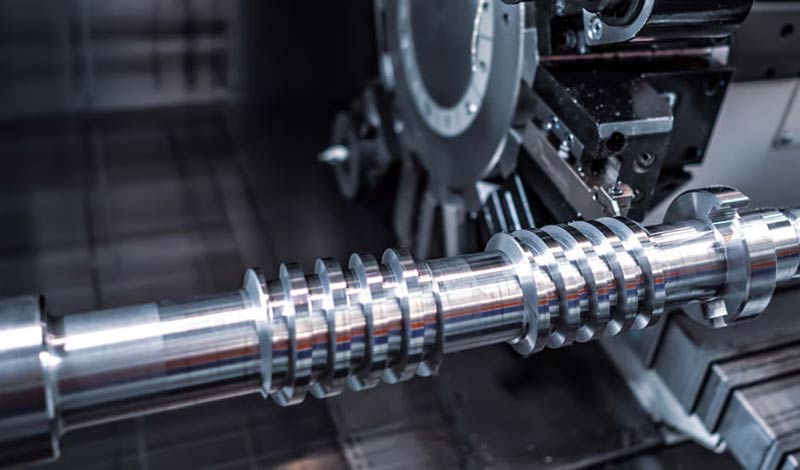

We provide custom metal processing services for a wide range of industries. From stamping and sheet metal fabrication to CNC machining and brazing, we deliver manufacturing services with reliable quality and on-time delivery.

We specialize in a variety of metal processing services to meet different project needs. Explore our core capabilities and find the right manufacturing solution for your parts.

Performing precise bending, forming, and hole punching on sheet metal structures.

Suitable for load-bearing, structurally complex, and highly stable metal components.

Reliable brazing technology ensures strong and secure joints and a clean assembly.

We can custom manufacture compression springs, extension springs, and torsion springs.

Upload your drawing or send your requirements, and we will respond within 24 hours.

Support small batch to large volume production

Precision machining and stamping with tight tolerances

Aluminum, stainless steel, carbon steel, copper, nickel alloys

Dimensional measurement and final product testing

Our manufacturing services are backed by strict quality inspection capabilities to ensure every part meets customer requirements. From raw material verification to final product testing, we use precise measuring tools and standardized inspection procedures to guarantee accuracy, consistency, and reliability.

Have other questions?

Yes. We provide full OEM/ODM services based on customer drawings, samples, or technical requirements. Our engineering team supports process optimization, tooling development, prototyping, and mass production.

We work with a wide range of materials including carbon steel, stainless steel, iron, copper, aluminum, and nickel-based alloys, suitable for different industries and working conditions.

Our capabilities cover stamping, sheet metal bending, casting, forging, machining, spring manufacturing, and brazing, enabling one-stop production for complex metal components.

We implement an ISO-compliant quality management system with 18 quality inspection points throughout the production process, ensuring stable quality and batch consistency.

Simply send us your drawings, samples, or requirements. Our team will review your project and provide a professional quotation and technical proposal promptly.