Scaffolding is a temporary support and protection system composed of metal stamping/sheet metal structural components, pipes, and connectors. Its core function is to provide a stable working platform and safety protection for construction, equipment maintenance, and high-altitude operations.

Scaffolding is a temporary support and protection system composed of metal stamping/sheet metal structural components, pipes, and connectors. Its core function is to provide a stable working platform and safety protection for construction, equipment maintenance, and high-altitude operations.

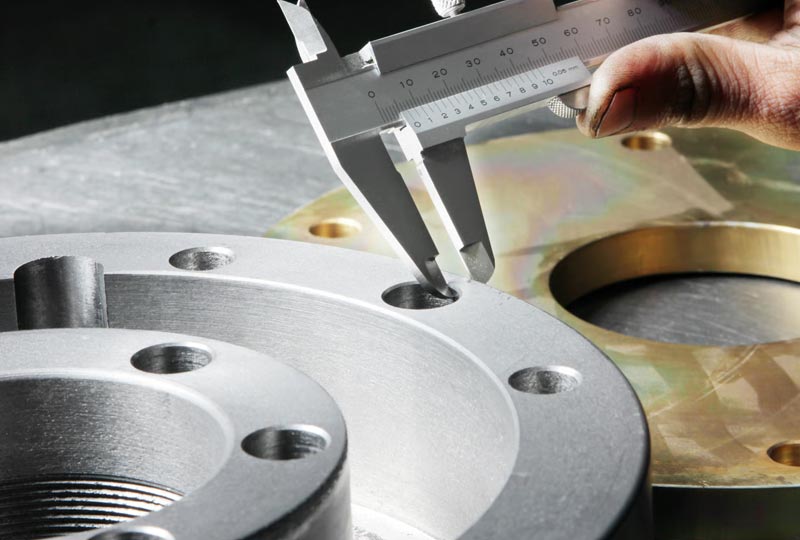

Its core components, such as uprights, crossbars, scaffolding planks, and buckles, are largely formed using precision stamping, sheet metal bending, and welding processes, possessing characteristics of high strength, easy assembly and disassembly, and strong versatility. It supports customized designs based on working height, load requirements, and specific working conditions.

It is widely used in construction engineering, industrial maintenance, municipal construction, and other fields.

Applicable Scenarios

1. Construction Engineering Field

Applicable Products: Clamp-type steel pipe scaffolding, ringlock scaffolding; Application Scenarios: Residential/commercial building construction, bridge construction, steel structure installation, exterior wall decoration; Scenario Requirements: Outdoor open-air environment, requiring resistance to wind and rain corrosion, capable of bearing heavy loads of construction personnel and materials, and suitable for high-altitude work protection; Process Value: Hot-dip galvanized stamped connectors resist outdoor corrosion, ringlock stamped disc structure improves installation efficiency and ensures construction safety.

2. Industrial Inspection and Equipment Maintenance Field

Applicable Products: Frame scaffolding, non-standard customized scaffolding; Application Scenarios: Factory workshop equipment inspection, boiler maintenance, large machinery assembly, chemical equipment maintenance; Scenario Requirements: Indoor/semi-outdoor environment, requiring adaptation to irregular equipment structures, easy assembly and disassembly, and resistance to oil and corrosion in some cases; Process Value: Lightweight sheet metal frame facilitates movement within the workshop, non-standard stamped connectors adapt to equipment gaps, and guardrails ensure the safety of maintenance personnel.

3. Municipal Engineering and Public Facilities Field

Applicable Products: Frame scaffolding, ringlock scaffolding; Application Scenarios: Road maintenance, bridge maintenance, street lamp/billboard installation, subway construction; Scenario Requirements: Outdoor mobile operations, requiring quick assembly and disassembly, adaptation to narrow spaces on both sides of the road, and high anti-overturning performance; Process Value: Frame scaffolding requires no tools for assembly and disassembly, ringlock structure has strong wind resistance and stability, and stamped locking pins ensure safety during temporary operations.

4. Shipbuilding and Marine Engineering Field

Applicable Products: Stainless steel ringlock scaffolding, non-standard customized scaffolding; Application Scenarios: Ship construction, hull repair, offshore platform maintenance; Scenario Requirements: High salt spray and high humidity corrosive environment, requiring resistance to seawater corrosion, and adaptation to the curved and irregular spaces of the hull; Process Value: 316 stainless steel stamped connectors pass salt spray test ≥1000h, non-standard sheet metal frame fits the hull structure, ensuring stability during offshore operations.

5. Interior Decoration and Short-Term Work Fields

Suitable Products: Lightweight portal frame scaffolding, small-scale modular scaffolding; Application Scenarios: Office building renovation, shopping mall refurbishment, residential interior decoration, exhibition hall construction; Scene Requirements: Indoor environment, limited space, easy to move and stack, convenient assembly and disassembly, minimal damage to the floor; Process Value: Lightweight aluminum alloy sheet metal components, rapid assembly of portal frame structure, stamped locking pins to ensure work safety, suitable for short-term temporary work needs.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.