The suspended platform, equipped with a dedicated safety lock, provides secure locking and fall protection during lifting and lowering operations. It is widely used in construction, equipment maintenance, high-altitude installation, and other applications.

• Suspended platforms are mobile aerial work platforms. Their core structural components (frame, base plate, guardrails, and connectors) are formed through metal stamping, bending, and welding processes. They are equipped with specialized suspended platform locks to ensure safe locking and fall protection during lifting and lowering. They are widely used in construction, equipment maintenance, and high-altitude installation.

The product supports full-dimensional non-standard customization, allowing for adjustments to structure and performance based on customer requirements for working height, load capacity, and operating environment.

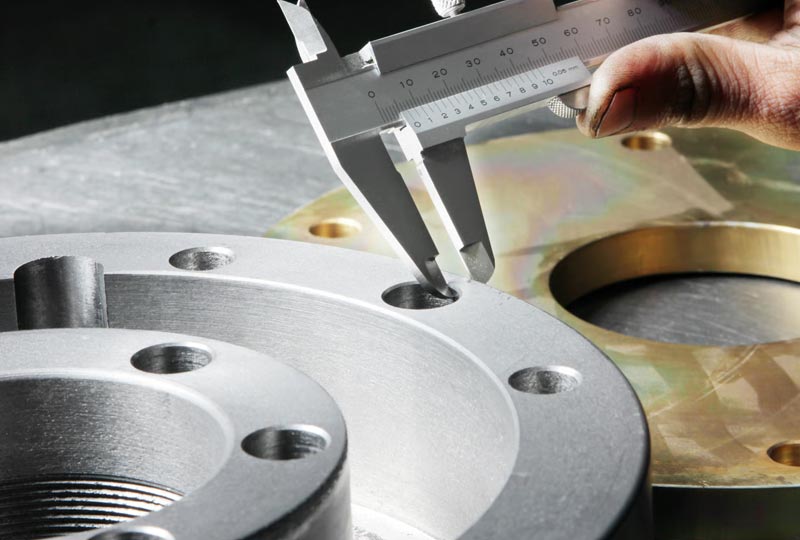

• Suspended platform locks are the core safety components of the suspended platform. They are manufactured through precision stamping and assembly processes and are divided into three types: fall protection locks, hoist locks, and manual locking devices. Their primary function is to automatically lock the platform in case of abnormal lifting or lowering, preventing falls or tilting.

Applicable Scenarios

Suspended Platform Applications

1. Building Exterior Engineering: Construction suspended platforms are used for high-altitude work such as exterior wall painting, tile laying, and glass curtain wall installation, replacing traditional scaffolding and improving construction efficiency. They require a thickened stamped main frame and anti-slip base plate to withstand outdoor wind, rain, and strong winds at high altitudes.

2. Industrial Equipment Maintenance: Industrial maintenance suspended platforms are used for the inspection and maintenance of large equipment in factories, power transmission towers, and wind turbine blades. They are suitable for working in confined spaces and require a lightweight aluminum alloy stamped frame and a foldable operating platform for easy transportation and installation.

3. Household High-Altitude Work: Lightweight household suspended platforms are used for small tasks such as villa exterior wall cleaning, balcony plant maintenance, and roof repairs. They do not require professional operators and need a small stamped frame and a colored powder-coated finish to match home decoration styles.

4. Ship/Marine Engineering: Stainless steel suspended platforms are used for ship hull rust removal and painting, and maintenance of offshore platform equipment. They require 316 stainless steel stamped parts to withstand high salt spray corrosion environments.

Suspended Platform Lock Application Scenarios

Suspended platform locks are mandatory for use with various types of suspended platforms. The core application scenarios are as follows:

1. Construction site scenarios: Automatic fall protection locks are used with construction suspended platforms to prevent falls caused by wire rope breakage or hoist failure, ensuring the safety of construction workers;

2. Industrial maintenance scenarios: Hoist locks are used with industrial suspended platforms to provide emergency braking in case of power failure at high altitudes, preventing uncontrolled descent of the platform;

3. Household scenarios: Manual locking devices are used with lightweight suspended platforms, providing manual locking and fixing during operation to prevent platform swaying and ensure safe operation;

4. Special hazardous scenarios: Explosion-proof suspended platform locks are used with explosion-proof suspended platforms, suitable for high-altitude work in flammable and explosive environments such as chemical workshops and oil and gas fields.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.