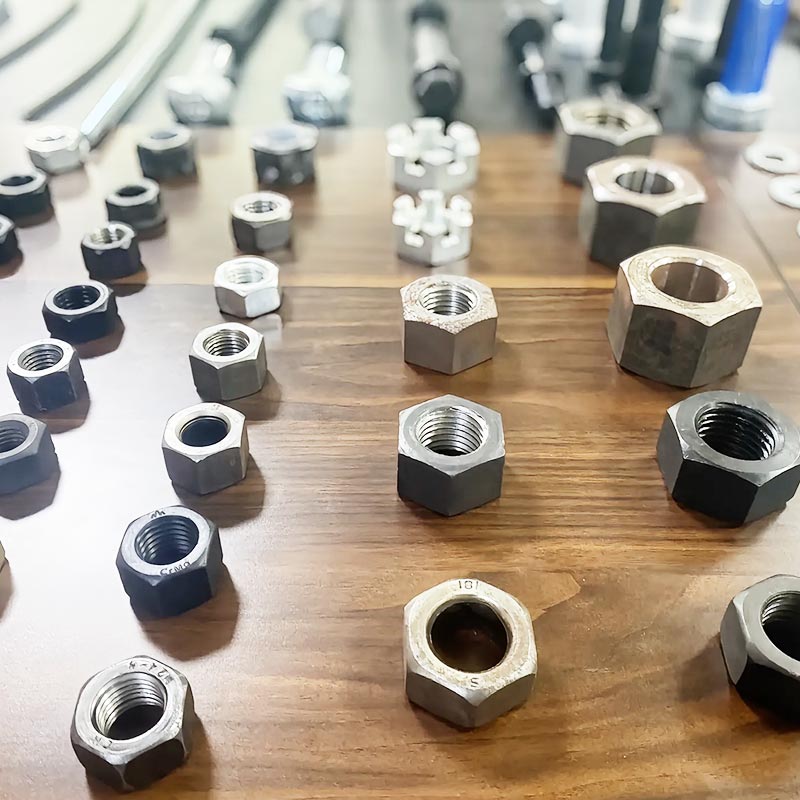

Fasteners are standardized metal connecting components manufactured through precision stamping, cold heading, turning, and heat treatment processes. Their core function is to securely connect two or more parts ianto a single unit.

Fasteners are standardized metal connecting components manufactured through precision stamping, cold heading, turning, and heat treatment processes. Their core function is to securely connect two or more parts into a single unit, offering both detachability and structural stability.

Their core components (bolt heads, nut cavities, and washer surfaces) are largely formed using metal stamping processes, supporting both mass production of standard parts and custom manufacturing of non-standard parts.

They are widely used in all fields, including industrial manufacturing, construction engineering, electronics and electrical appliances, and agricultural machinery.

Applicable Scenarios

1. Automotive Manufacturing and Parts Industry

Core Fasteners:

10.9/12.9 grade high-strength bolts, anti-loosening flange nuts, stamped blind rivets, welding studs, locating pins

Scenario Requirements:

Long-term operation under vibration conditions, requiring extremely high reliability and fatigue resistance; suitable for assembly in multiple parts of the vehicle body, chassis components, engine components, and interior parts; some require resistance to engine oil and high-temperature environments, while also meeting the needs of automated mass assembly.

Process Adaptation Value:

The flange nut’s bearing surface features stamped anti-slip teeth, combined with cold heading technology to ensure uniform tooth shape, preventing loosening during high-frequency vibrations of the vehicle; the blind rivet uses a stamped hollow rod design, directly fastening the vehicle body sheet metal after riveting, replacing traditional welding processes and improving assembly efficiency by more than 30%; the high-strength bolt head has stamped reinforcing ribs, and its tensile strength meets standards after heat treatment, suitable for heavy-duty connection scenarios in the chassis.

2. Construction Engineering and Steel Structure Industry

Core Fasteners:

Hot-dip galvanized expansion bolts, anchor bolts, steel structure high-strength studs, flange nuts, stamped flat washers, self-tapping and self-drilling screws

Scenario Requirements:

Mostly outdoor environments, requiring resistance to wind, rain, ultraviolet rays, and high salt spray corrosion in coastal areas; suitable for curtain wall installation, bridge reinforcement, steel structure splicing, and precast component fastening, with strict requirements for load-bearing capacity, rust and corrosion resistance, and ease of installation.

Process Adaptation Value:

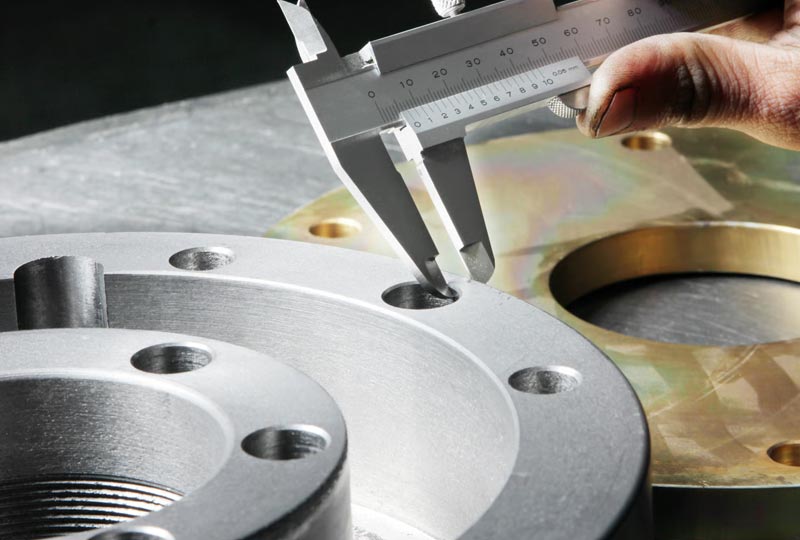

Bolts and nuts undergo hot-dip galvanizing and stamping anti-corrosion treatment, with salt spray testing ≥500h, effectively resisting outdoor corrosive environments and extending service life; the expansion tube uses a precisely tapered design, ensuring a tight fit with the wall after expansion, without the risk of loosening; the thickness tolerance of the stamped flat washer is controlled within ±0.02mm, which can evenly distribute the fastening pressure and prevent deformation of steel structure sheet metal parts.

3. Electronics, Electrical Appliances, and 3C Industries

Core Adapted Fasteners

Micro-precision screws (M1-M3), copper conductive fasteners, ultra-thin stamped washers, self-locking nuts, stamped clips

Scenario Requirements and Characteristics

Miniaturized and precision components, limited assembly space; requires fastening of circuit boards, housings, connectors, heat dissipation components, etc., some requiring conductive properties, and compatibility with automated pick-and-place machines and robotic assembly, with extremely high requirements for dimensional accuracy and surface cleanliness.

Process Adaptation Value

The heads of micro-screws are formed with cross/internal hexagon slots through CNC stamping, with a tolerance of ≤0.02mm, precisely adapting to the torque transmission of automated assembly equipment; copper washers are flattened by stamping, with no burrs on the surface, ensuring stable conductivity and low contact resistance; stamped clips are integrally formed, requiring no additional fasteners, and can quickly snap onto the sheet metal housing of electronic devices, improving assembly efficiency.

4. Agricultural Machinery and Equipment Industry

Core Adapted Fasteners

Galvanized bolts, stamped locating pins, agricultural machinery-specific studs, self-locking nuts, blind rivets

Scenario Requirements and Characteristics

Long-term exposure to humid, dusty, and acidic/alkaline soil environments in farmland, requiring strong rust and corrosion resistance; suitable for fastening plows, frames, conveyor chain plates, gearbox components, etc., requiring resistance to vibration, impact, and heavy-duty working conditions of agricultural machinery, and easy field maintenance and replacement.

Process Adaptation Value

The fastener surface is treated with galvanized stamping, forming a dense anti-rust layer, resisting soil acid and alkali corrosion, and reducing field failures; the locating pins are stamped with a 1:50 standard taper, precisely positioning agricultural machinery transmission components, avoiding abnormal noise and component wear; blind rivets are suitable for splicing agricultural machinery sheet metal frames, requiring no welding, allowing for quick field repair and replacement, reducing maintenance costs.

5. Medical Device Industry

Core Compatible Fasteners

316 Stainless Steel Precision Screws, Titanium Alloy Studs, Stamped Rivets, Sterile Washers

Scenario Requirements and Characteristics

Must meet medical-grade hygiene standards, be free of hygiene blind spots, easy to clean and disinfect, and some need to be compatible with implantable and diagnostic equipment; strict requirements for dimensional accuracy, biocompatibility, and corrosion resistance are necessary to prevent heavy metal leaching and bacterial growth.

Process Adaptation Value

316 stainless steel fasteners are processed by CNC stamping and polishing, resulting in burr-free edges and smooth surfaces, eliminating hygiene blind spots and allowing for high-temperature sterilization; precision screws have a tolerance control of ±0.03mm, ensuring the operating accuracy of medical beds, surgical instruments, and other equipment; titanium alloy studs are specially treated after stamping, possessing excellent biocompatibility and meeting the needs of some implantable medical devices.

6. Sheet Metal/Hardware Processing and Automation Equipment Industry

Core Compatible Fasteners

Self-tapping Screws, Blind Rivets, Flange Nuts, Stamped Connectors, Non-standard Custom Fasteners

Scenario Requirements and Characteristics

Suitable for sheet metal splicing, frame assembly, and fastening of automation equipment covers; needs to replace welding processes to improve efficiency; some need to be adapted to the irregular structures of non-standard equipment, while ensuring seamless assembly with stamped/sheet metal parts.

Process Adaptation Value

Blind rivets feature a stamped hollow shaft design, allowing for direct fastening of two sheet metal parts after riveting, eliminating the need for welding and preventing sheet metal deformation and weld corrosion; non-standard fasteners can be precisely stamped according to the mounting holes of the sheet metal parts, meeting the fastening needs of irregularly shaped frames and covers; flange nuts have a stamped anti-slip surface, preventing slippage when fastening sheet metal parts and improving structural stability. 7. Aerospace and High-End Equipment Industry

Core Adapted Fasteners

Titanium alloy high-strength bolts, high-temperature alloy fasteners, precision stamped pins, anti-loosening fasteners

Scenario Requirements and Characteristics

Must meet stringent requirements such as lightweighting, high temperature resistance, resistance to extreme temperature differences, and high strength, suitable for fastening aircraft fuselages, engine components, satellite equipment, etc. The requirements for dimensional accuracy, reliability, and compliance far exceed those of ordinary industries.

Process Adaptation Value

Titanium alloy fasteners utilize a composite stamping + heat treatment process, balancing high strength and lightweighting, adapting to the weight reduction needs of the aviation industry; high-temperature alloy fasteners are formed by stamping and then undergo special treatment, capable of withstanding extreme temperature differences from -200℃ to 800℃, ensuring connection stability in extreme environments; precision pins have a stamping accuracy of ±0.01mm, adapting to the precise positioning needs of high-end equipment.

8. Warehousing, Logistics and Cold Chain Equipment Industry

Core Adapted Fasteners

Galvanized bolts, stamped rack connectors, cold chain specific anti-corrosion nuts, roller axle pins

Scenario Requirements and Characteristics

Suitable for fastening warehouse racks, logistics conveying equipment, cold chain refrigerated trucks, etc. Racks need to bear heavy loads, and cold chain equipment needs to withstand low temperatures and high humidity corrosion. High demands are placed on the load-bearing capacity and corrosion resistance of fasteners.

Process Adaptation Value

Rack connectors are formed by stamping + welding reinforcement, providing strong load-bearing capacity, adapting to the multi-layer heavy-load requirements of racks; cold chain specific fasteners use galvanized + electrophoretic composite treatment, with a salt spray test ≥600h, resistant to low temperature and high humidity corrosion; roller axle pins have precise stamped diameters, ensuring smooth operation of logistics conveying equipment rollers and reducing jamming failures.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.