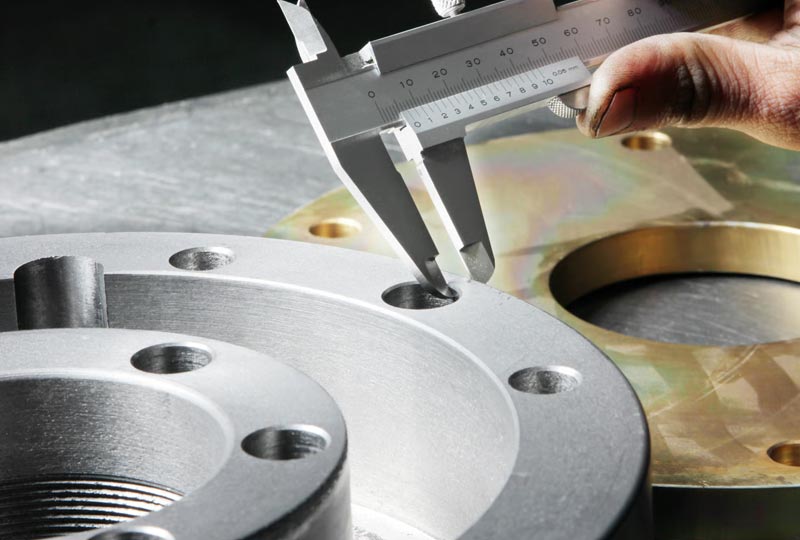

Chain plates are modular conveyor components manufactured through precision stamping, bending, punching, and assembly processes. Their core function is to work in conjunction with sprockets and drive shafts to achieve continuous, stable, and directional material transport.

Chain plates are modular conveyor components manufactured through precision stamping, bending, punching, and assembly processes. Their core function is to work in conjunction with sprockets and drive shafts to achieve continuous, stable, and directional material transport, while also possessing load-bearing, wear-resistant, and anti-deviation characteristics.

The individual links of the chain plate are formed from metal sheets through stamping, and can be assembled into conveyor chains of varying lengths and widths using pins and clips. They support full-dimensional non-standard customization and are widely used in automated production lines, warehousing and logistics, food processing, and new energy equipment.

Applicable Scenarios

1. Automated Production Lines / Automotive Manufacturing

Suitable Products: Heavy-duty conveyor chains, custom-shaped conveyor chains

Application Areas: Automotive parts assembly lines, engine block conveying lines, home appliance casing painting lines

Core Function: Achieves stable conveying and precise positioning of heavy workpieces; wear-resistant chains withstand high-frequency operation of the production line, reducing equipment maintenance costs.

2. Warehousing and Logistics / Express Delivery Sorting

Suitable Products: Standard conveyor chains, anti-slip conveyor chains

Application Areas: Express delivery sorting lines, e-commerce warehousing and sorting lines, automated warehouse entry and exit conveying lines

Core Function: Flexible chain splicing, supports high-speed sorting (speed ≥ 3m/s), anti-slip structure prevents package slippage, improving sorting efficiency.

3. Food Processing / Pharmaceutical Packaging

Suitable Products: Stainless steel anti-slip conveyor chains, food-grade conveyor chains

Application Areas: Fruit and vegetable cleaning and sorting lines, meat processing conveying lines, pharmaceutical bottle filling lines

Core Function: 304/316 stainless steel chains are corrosion-resistant and easy to clean, meeting FDA/GMP hygiene standards, preventing material contamination and ensuring food and pharmaceutical safety.

4. New Energy Equipment

Suitable Products: Heavy-duty conveyor chains, aluminum alloy lightweight conveyor chains

Application Areas: Power battery module assembly lines, photovoltaic module conveying lines, energy storage equipment casing painting lines

Core Function: Heavy-duty chains bear the weight of battery modules, aluminum alloy chains achieve lightweight conveying, and stainless steel materials withstand the acidic and alkaline environments of the production workshop.

5. Mining / Construction Machinery

Suitable Products: Manganese steel hot-dip galvanized conveyor chains, heavy-duty conveyor chains

Application Areas: Ore sorting and conveying lines, sand and gravel aggregate conveying lines, construction machinery parts production lines

Core Function: Hot-dip galvanized chains are corrosion-resistant and wear-resistant, withstanding harsh mining conditions; high-strength structure can carry tons of material, extending service life. 6. Electronics / 3C Manufacturing Sector

Applicable Products: High-precision irregularly shaped chain plates, anti-static chain plates

Application Areas: Mobile phone component assembly lines, circuit board testing lines, electronic component sorting lines

Core Function: High-precision chain plates ensure precise transportation of electronic components, and the anti-static coating prevents electrostatic damage to components, improving product yield.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.