Automation equipment is a complete set of intelligent equipment integrating metal stamping/sheet metal structural components, electromechanical control systems, and transmission components.

Automation equipment is a complete set of intelligent equipment integrating metal stamping/sheet metal structural components, electromechanical control systems, and transmission components.

Its core function is to replace manual labor through program control, achieving automated operation of processes such as material handling, processing and assembly, inspection and sorting, and packaging and palletizing.

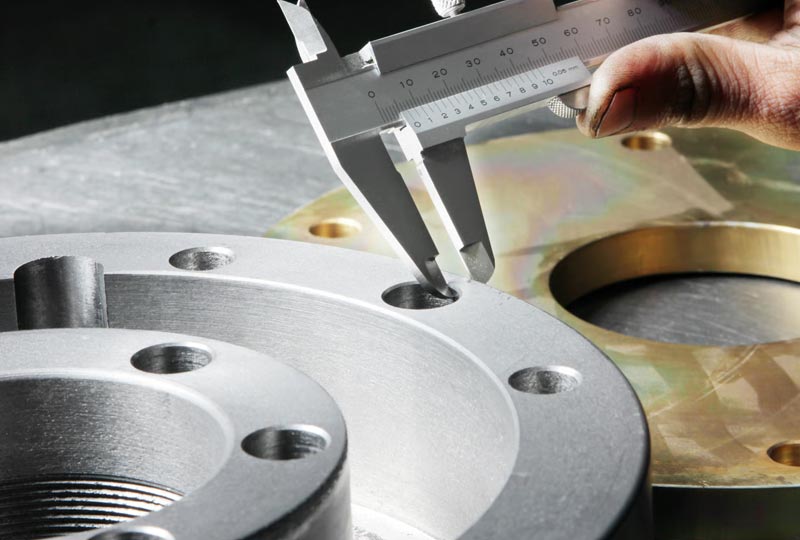

The core structural components of the equipment (frame, protective cover, conveyor track, tooling fixtures) are formed through precision stamping, sheet metal bending, and welding processes, supporting full-dimensional non-standard customization according to overseas customers’ workshop layout, production capacity requirements, and process flow.

It is widely applicable to fields such as automotive manufacturing, new energy, electronics and electrical appliances, and metal processing.

Applicable Scenarios

1. Automotive Manufacturing/Parts Sector

Applicable Products: Stamping automation production lines, automotive parts assembly machines, body parts conveyor lines; Application Stages: Automotive stamping parts processing, chassis parts assembly, body parts inspection and sorting; Core Function: Sheet metal frames and stamping tooling ensure high-strength and high-precision operation of equipment, automated operations increase production capacity, and meet the needs of large-scale production in overseas automotive factories.

2. New Energy Equipment Sector

Applicable Products: Battery module assembly lines, photovoltaic module conveying and testing equipment, energy storage equipment automated assembly machines; Application Stages: Power battery cell assembly, photovoltaic panel testing, energy storage box welding and conveying; Core Function: Stainless steel stamping/sheet metal parts withstand workshop acid and alkali environments, precise positioning systems ensure the assembly accuracy of new energy components, and improve product yield.

3. Electronics/3C Sector

Applicable Products: Electronic component insertion equipment, precision component visual inspection machines, anti-static conveyor lines; Application Stages: Mobile phone/computer parts assembly, circuit board testing, electronic component sorting and packaging; Core Function: Anti-static sheet metal workbenches and stamping tooling prevent component damage, high-precision testing equipment ensures dimensional consistency of electronic components, and meets the miniaturization and precision requirements of consumer electronics.

4. Hardware Processing/Sheet Metal Manufacturing Sector

Applicable Products: Fully automatic stamping feeding machines, automatic hardware sorting machines, sheet metal bending automation production lines; Application Stages: Batch processing of hardware stamping parts, sheet metal bending and assembly, finished product inspection and packaging; Core Function: Strong process synergy, seamless connection between equipment and hardware stamping/sheet metal processes, reducing manual intervention, lowering production costs, and adapting to large-scale production in overseas hardware processing plants.

5. Warehousing and Logistics/Packaging Sector

Applicable Products: Automated chain plate conveyor lines, fully automatic palletizing robots, warehousing and sorting equipment; Application Stages: E-commerce warehousing and sorting, industrial product packaging and palletizing, logistics turnover and transportation; Core Function: Heavy-duty sheet metal frames have strong load-bearing capacity, and stamped chain plates are wear-resistant and corrosion-resistant, adapting to high-frequency conveying operations, improving warehousing and logistics efficiency, and suitable for large overseas warehousing centers and factories. 6. Medical Devices/Precision Instruments Field

Applicable Products: Medical component assembly machines, precision instrument testing equipment, sterile workshop conveyor lines; Application Stages: Surgical instrument assembly, diagnostic equipment component testing, medical consumable packaging; Core Function: 316 stainless steel sheet metal parts meet medical-grade hygiene standards, sealed structure prevents dust contamination, high-precision positioning ensures the assembly accuracy of medical components, and is suitable for the sterile production needs of overseas medical equipment factories.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.