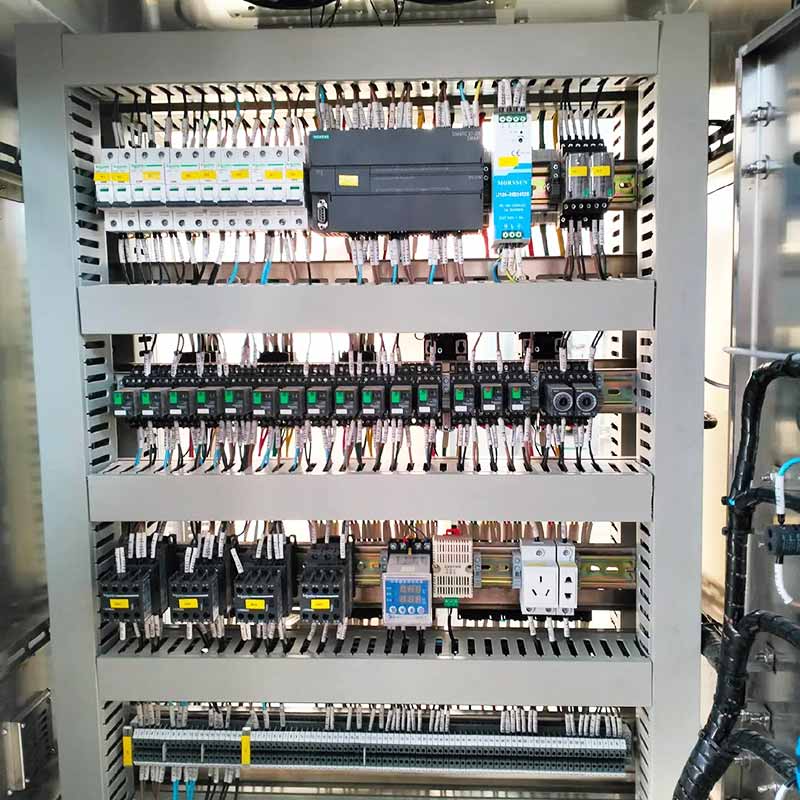

A transformer control cabinet is a complete electrical equipment unit integrating metal stamping/sheet metal enclosure, electrical control components, protection systems, and terminal blocks. Its core functions are to monitor, control, protect, and distribute power to the transformer.

A transformer control cabinet is a complete electrical equipment system integrating metal stamping/sheet metal cabinets, electrical control components, protection systems, and wiring terminals. Its core functions are to monitor, control, protect, and distribute power to the transformer, while ensuring electrical safety and stable equipment operation.

The main body of the cabinet, door panels, mounting brackets, cooling grilles, and other core structures are manufactured using precision metal stamping/sheet metal processes, supporting both standardized mass production and non-standard customization.

It is widely applicable in power transmission and distribution, industrial production, building power distribution, and other scenarios.

Application Scenarios

Industrial Production Workshops: Dry-type transformer control cabinets, non-standard customized control cabinets; with numerous power-consuming devices and large load fluctuations, precise control of power distribution is required to ensure continuous equipment operation;

Some workshops have dust and oil contamination, requiring voltage stabilization, distribution, and protection of the transformer output power to prevent equipment overload damage;

The cabinet features a sealed structure to prevent dust and oil contamination;

Sheet metal cabinet with stamped sealing grooves + rubber sealing strips, IP54 protection rating, isolating workshop dust and oil; standardized mounting holes on the mounting plate facilitate maintenance and replacement of electrical components.

Urban and Rural Power Transmission and Distribution: Box-type transformer control cabinets, oil-immersed transformer control cabinets, covering residential areas, commercial areas, and industrial parks; requiring outdoor installation, resistant to wind, rain, lightning, and high humidity; some areas are coastal high-salt fog environments, achieving 10kV/35kV high-voltage to low-voltage (380V/220V) conversion to ensure stable power supply for residents and businesses;

Features lightning protection and overload protection; outdoor cabinet with stamped rain eaves + hot-dip galvanizing anti-corrosion treatment, salt spray test ≥ 800h;

Pre-assembled modular design, reducing on-site installation time by 50%.

Building Engineering Power Distribution: Dry-type transformer control cabinets, box-type transformer control cabinets, indoor and outdoor power distribution for new buildings, shopping malls, and office buildings; requiring adaptation to building layouts, some requiring concealed installation, providing stable power supply for lighting, air conditioning, elevators, and other equipment within the building;

Features fire linkage function, automatically cutting off non-firefighting power during a fire.

The cabinet adopts a modular stamped structure, allowing for separate transportation and adaptation to narrow spaces for lifting; the door panel has stamped fire linkage interfaces, integrating fire alarm signals.

New Energy Power Generation Systems: Non-standard customized transformer control cabinets, supporting photovoltaic power plants and wind power plants; requiring anti-reverse charging and anti-islanding functions, supporting grid-connected power generation;

Operating environments are mostly remote outdoor areas, requiring voltage regulation of the new energy power generation system to achieve stable grid connection;

Monitoring power generation to ensure safe system operation. The cabinet is made of 316 stainless steel through stamping, capable of withstanding harsh climates in remote areas;

The internal compartments are separated by stamping, isolating power generation and distribution components to prevent electromagnetic interference.

Chemical/Mining Explosion-Proof Scenarios: Explosion-proof oil-immersed transformer control cabinet, suitable for environments with flammable and explosive gases/dust, requiring explosion-proof and corrosion-resistant features, and complying with explosion-proof certification standards;

The load consists of heavy-duty equipment, providing safe power to chemical reactors and mining equipment; the explosion-proof structure prevents electrical sparks from igniting flammable and explosive media.

The cabinet features stamped explosion-proof pressure relief vents and uses welded sealing technology, complying with Ex d IIB T4 explosion-proof standards; the surface is coated with anti-corrosion paint, resistant to chemical acid and alkali corrosion.

Temporary Construction Sites: Box-type transformer control cabinet (mobile), suitable for temporary and dispersed power needs, requiring quick installation and easy mobility;

The construction site environment is complex, with risks of vibration and collision; it provides temporary power distribution for construction equipment such as tower cranes, mixers, and welding machines;

It features overload and leakage protection to ensure the safety of construction personnel.

The cabinet has stamped lifting lugs and mobile wheel mounting bases for quick lifting and transportation; the sheet metal frame has stamped reinforcing ribs, providing strong impact resistance and resistance to construction site vibrations.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

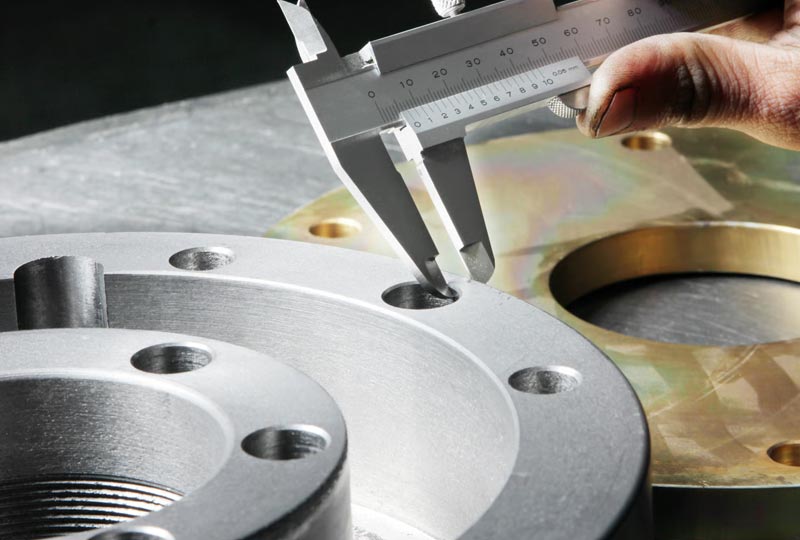

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.