Musical instruments are a blend of art and industry, combining metal stamping/sheet metal forming, precision machining, and acoustic tuning. Their core function is to produce sounds of specific frequencies through vibration, conveying musical expression.

Musical instruments are a blend of art and industry, combining metal stamping/sheet metal forming, precision machining, and acoustic tuning. Their core function is to produce sounds of specific frequencies through vibration, conveying musical expression.

The core structural components of brass instruments, percussion instruments, and electronic musical instruments are largely manufactured using metal stamping/sheet metal processes.

The finished products possess excellent acoustic performance, structural stability, and aesthetic appeal, and support comprehensive non-standard customization based on acoustic requirements, design, and dimensions.

They are widely suitable for professional performances, music education, home entertainment, and other scenarios.

The metal stamping/sheet metal process for musical instruments requires balancing structural precision and acoustic performance. The core process is divided into five main stages, each affecting the final quality of the instrument, and can be integrated with automated equipment to improve production capacity.

(1) Preliminary Preparation and Cutting

1. Material Selection and Pre-treatment: Select the appropriate metal sheet material based on the type of musical instrument (e.g., brass sheet for brass instruments, cold-rolled steel sheet for drum shells), and perform degreasing and rust removal to ensure the subsequent stamping/sheet metal forming effect;

2. Precise Cutting: Use CNC laser cutting or shearing machines for cutting, controlling the sheet size tolerance to ±0.1mm, to meet the forming requirements of core components such as brass instrument resonance tubes and drum shells, laying the foundation for the stamping process.

(2) Core Stamping Process

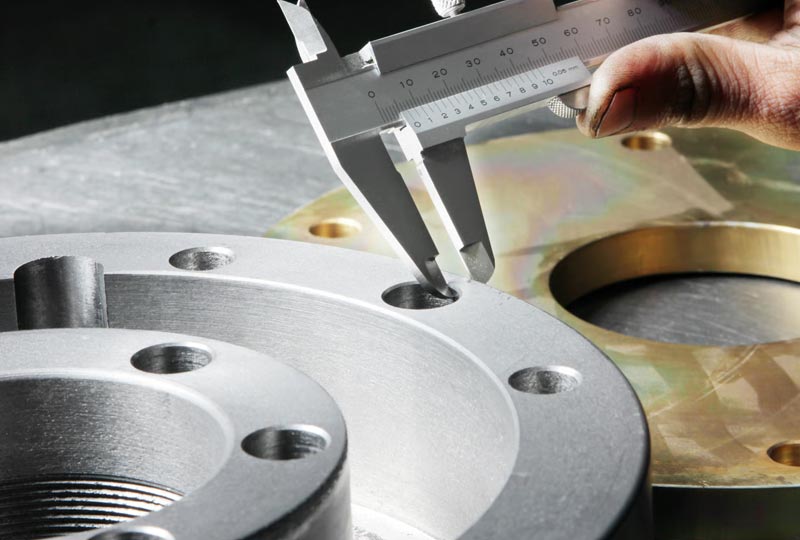

1. Forming Stamping: For precision components such as mouthpieces, piston valve bodies, and key brackets, use CNC stamping machines with customized molds for forming. The tolerance of key parts such as keyholes and positioning holes is ≤0.02mm, ensuring assembly accuracy and airtightness;

2. Deep Drawing: Used for curved parts such as bell mouths and pickup housings, multi-stage deep drawing is employed, controlling the drawing speed to prevent sheet cracking and ensuring uniform wall thickness (deviation ≤0.03mm) to avoid affecting acoustic vibration;

3. Auxiliary Stamping: Includes processes such as punching, trimming, and flanging. Edge deburring and polishing are performed to prevent scratches and ensure smooth assembly, such as polishing the edges of cymbal sheets after stamping to improve the vibration sound quality. (3) Sheet Metal Bending and Forming

1. Precision Bending: For components such as resonance tubes, drum shells, and instrument bodies, CNC bending machines are used for bending, with an angle tolerance of ±0.5°. The resonance tubes of brass instruments require multiple bending processes to ensure smooth airflow;

2. Welding and Reinforcement: Sheet metal parts are welded using argon arc welding or laser welding, resulting in smooth welds without pores. Drum shells undergo sealing tests after welding to prevent air leaks that could affect resonance; key areas are reinforced with stamped ribs to improve structural stability, such as the welded and stamped reinforcement plates on instrument stands after bending.

(4) Surface Treatment Process

1. Rust and Corrosion Prevention Treatment: Zinc plating, nickel plating, or electrophoretic coating is used, with a salt spray test result of ≥300 hours, suitable for humid environments such as stages and outdoor performances, e.g., zinc plating of drum stands and instrument stands;

2. Aesthetic and Texture Treatment: Brass instruments undergo brushing and polishing to achieve a metallic luster; electric guitar bodies use electrostatic powder coating (custom colors available) or anodizing, balancing aesthetics and wear resistance;

3. Acoustic Optimization Treatment: Some components (such as cymbal plates) undergo quenching and tempering after stamping to adjust metal hardness and optimize vibration frequency, ensuring stable sound quality.

(5) Assembly and Acoustic Tuning

1. Precision Assembly: Stamped/sheet metal parts are assembled with other components (such as strings, pickups, and pistons). Automated assembly equipment is used to improve consistency, and moving parts such as keys and pistons must be ensured to be flexible and free of jamming;

2. Acoustic Tuning: Professional technicians tune the instruments, optimizing the tone and pitch by fine-tuning the tightness and sealing of stamped parts (such as the piston clearance of brass instruments), ensuring compliance with professional performance standards;

3. Finished Product Inspection: Including appearance inspection, dimensional re-inspection, and acoustic testing. Defective products are reworked to ensure consistent quality for every instrument.

(6) Collaborative Application of Automated Equipment

Automated equipment can be adapted to improve production capacity and precision. For example, fully automatic stamping and feeding machines can be used for the mass stamping of key brackets and cymbal blanks, automated assembly machines can be used for the rapid assembly of musical instrument parts, and visual inspection machines can be used to detect the dimensional accuracy of stamped parts. This meets the demands of large-volume overseas orders while ensuring consistent quality.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.