The transition from raw materials to the final product typically involves one or more of the following three processes: material removal (cutting), deformation, and assembly. If all of these processes are required, they are usually performed in chronological order.

Material Removal

This involves cutting the raw material to obtain the desired shape. To ensure maximum precision, speed, and efficiency, CNC waterjet, plasma, and laser cutting technologies are commonly used. In some cases, electrical discharge machining (EDM) may also be an option.

Laser Cutting

Laser cutting uses a high-density laser beam to directly irradiate the workpiece, precisely cutting the material by melting, vaporization, or combustion. Laser cutting machines are widely used in cutting, drilling, and engraving applications. The three common types of lasers include CO2 (carbon dioxide), Nd (neodymium), and Nd:YAG (neodymium-doped yttrium aluminum garnet), each with different advantages and applications in cutting technology.

CO2 lasers have high energy efficiency and high power output ratio, mainly used for cutting thin materials, engraving, and drilling. Nd lasers, while high in energy, have lower repetition efficiency and are suitable for engraving, drilling, and welding. Nd:YAG lasers have very high power output and can cut thicker materials, but their operating costs are higher than CO2 lasers.

Laser cutting machines can be used for processing metals such as aluminum, steel, copper, and stainless steel. They are best suited for cutting thin workpieces (maximum thickness of 15 mm for aluminum and 6 mm for steel), engraving, and drilling.

Waterjet Cutting

In waterjet cutting, a high-pressure water stream is focused onto the workpiece using a nozzle for cutting. For relatively soft materials such as rubber and wood, only water is used. For hard materials such as metals, a mixture of water and abrasive particles is used for cutting.

Waterjet cutting can cut materials of various thicknesses. The maximum thickness that can be cut depends on the type of material. Of all CNC cutting methods, waterjet cutting offers the highest precision, with tolerances between 0.05 mm and 0.1 mm. One reason for its high precision is that, unlike plasma and laser cutting, waterjet cutting does not generate heat, so there is no heat-affected zone in the workpiece. Waterjet cutting is very flexible and can be used to cut hard materials such as aluminum, steel, copper, stainless steel, and other metal alloys, as well as softer materials such as polymers, elastomers, wood, and foam.

Plasma Cutting

Plasma cutting works by applying heat and energy to a gas, converting it into plasma. The hot plasma is then accelerated by an inert gas or air and ejected from a cutting nozzle onto the workpiece. The plasma forms an electric arc with the workpiece, causing it to melt and cut. As an electrical process, plasma cutting can only process electrically conductive materials.

Plasma cutting machines can cut very thick materials, such as aluminum up to 300 mm and steel up to 200 mm, with a tolerance of 0.2 mm. Stainless steel, copper, and other metal alloys can also be processed using plasma cutting machines. Depending on the complexity of the required parts, 2-axis or 3-axis cutting machines can be used.

While plasma cutting machines are not as versatile or precise as waterjet and laser cutting machines, they are the best option for thick, electrically conductive metal parts because they are faster and more cost-effective when cutting such materials.

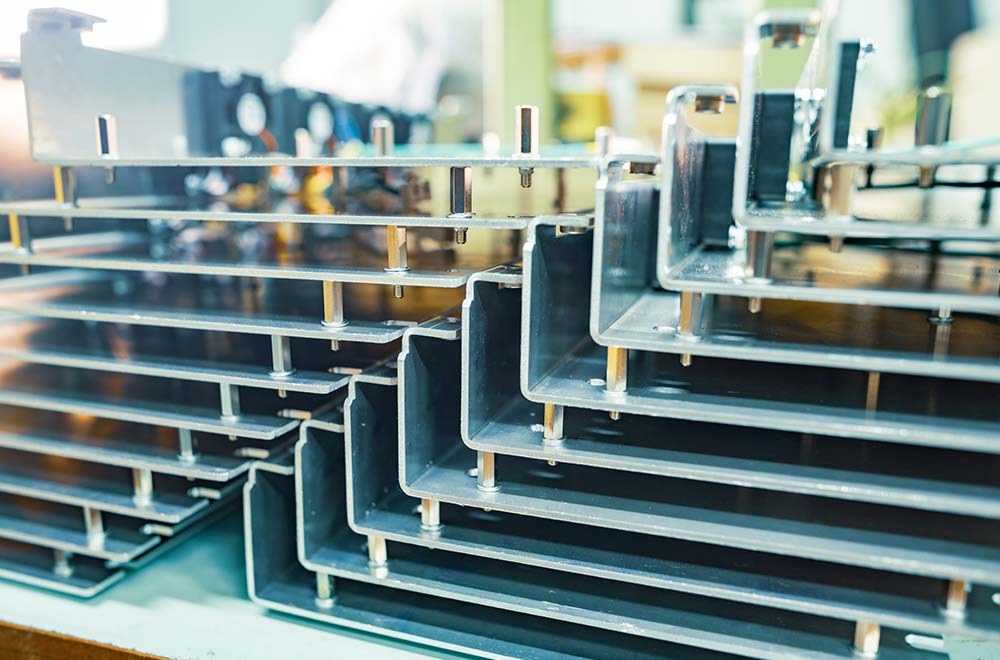

Forming

This process involves bending or shaping metal sheets into the desired shape by controlling the applied force. Forming processes include bending, shaping, stamping, and stretching using molds, hydraulic and electromagnetic brakes.

Assembly

This is the process of combining various processed workpieces to form the final product. Assembly processes include welding, brazing, riveting, and sometimes the use of adhesives.