Disposable tweezers are a handheld tool used in laboratories, medical settings, and for precision operations. Their core components are manufactured using high-strength stainless steel or medical-grade metal through stamping, precision drawing, and polishing processes.

Disposable tweezers are a handheld tool used in laboratories, medical settings, and for precision operations. Their core components (tweezer body, gripping head, and handle) are manufactured using high-strength stainless steel or medical-grade metal through stamping, precision drawing, and polishing processes, ensuring stable gripping, flexible operation, and a smooth surface.

The product is designed for single-use, eliminating the need for repeated sterilization and preventing cross-contamination, thus ensuring hygiene and safety. It is suitable for short-term experiments or medical procedures.

Disposable tweezers support multiple specifications and different head types for customization, allowing for design optimization based on gripping precision, comfort, and operating environment.

Typical Applications:

• Laboratory operations: Sample handling, reagent manipulation, and assistance in microscopic observation.

• Medical use: Fine manipulation in surgery, dentistry, and wound treatment.

• Electronic assembly: Gripping and handling of precision components, chips, and miniature devices.

• Cosmetics and beauty: Fine manipulation for false eyelash application, nail decoration, etc.

• Teaching and research: Auxiliary tools for biology, chemistry, and materials experiments.

Carbon steel, stainless steel, iron, copper, aluminum, nickel-based alloys

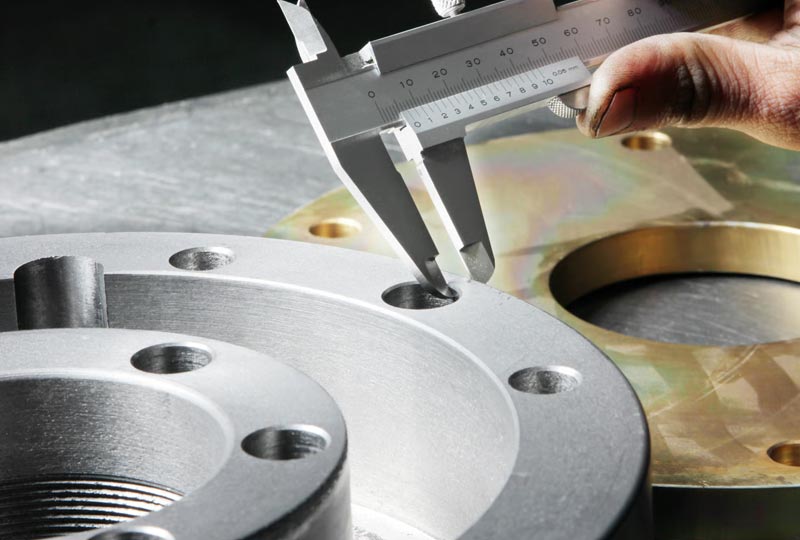

Custom sizes, structures, and precision requirements based on drawings or samples

Stamping, sheet metal bending, casting, forging, machining, spring manufacturing, brazing

Galvanizing, powder coating, painting, polishing, anodizing, plating

Customized shapes, multi-part assembly, functional integration

Logo marking, part number engraving, private labeling

Our metal products and customized solutions are widely used across multiple industries, meeting different performance and operating requirements.

We have been working with this team for several years. Their metal parts show excellent consistency across batches, and delivery schedules are always reliable. Communication is smooth, and technical support is professional.