The automation industry encompasses applications such as industrial robots, production line equipment, transmission mechanisms, and control systems. Metal products are used in supporting structures, transmission parts, frames, and assemblies, requiring high strength, high precision, wear resistance, and long-term reliability to ensure stable operation and efficient production of the equipment.

We are committed to providing the highest quality precision metal parts manufacturing services, including precision casting, investment casting, sand casting, and CNC machining. We offer customized solutions, and before mass production, we will provide a free sample for your testing and confirmation.

Features: Investment casting has high precision, can adapt to complex shapes, has smooth surface and little material waste.

Applications: Aerospace, precision machinery, automobiles, medical equipment, etc.

Features: Uses sand mold, which is low in cost and suitable for large and complex-shaped metal castings.

Applications: Automotive parts, mechanical structural parts, large castings.

Features: High precision, complex parts, and mass production.

Applications: Molds, medical device parts, aluminum alloy engine cylinder blocks/cylinder heads.

Robotic Arm: Frame, joint supports, mounting base, etc.

Transmission Mechanism: Gearbox housing, support frame, transmission support, etc.

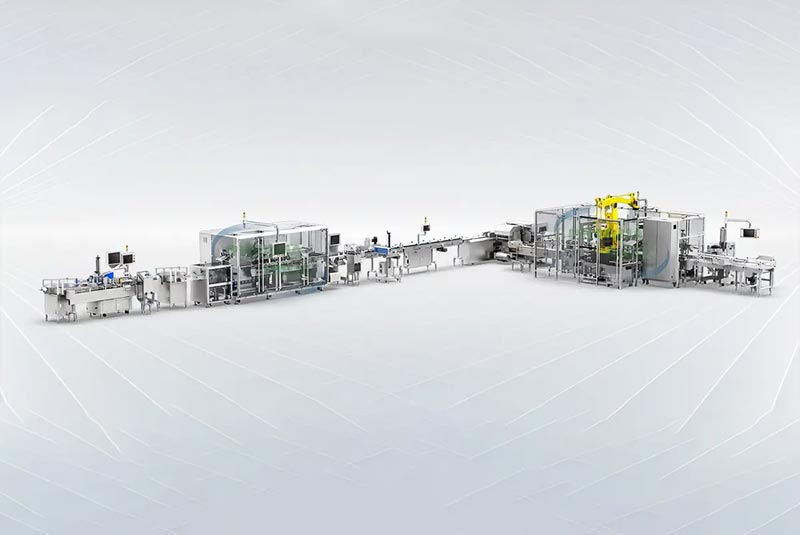

Production Line Equipment: Frame structure, brackets, connecting parts, etc.

Control and Assembly Equipment: Support base, fixing base, precision mounting parts, etc.

Suitable for load-bearing parts and frame structures, offering high strength, good wear resistance, and excellent machinability.

Suitable for frames, support components, and lightweight parts, reducing equipment weight and being easy to machine.

Used for parts in corrosive, precision, or easy-to-clean environments, such as controller brackets or assembly components.

Used for conductive parts, contacts, or miniature precision mechanisms.