The automotive stamping industry primarily provides metal stamping and processing services for body, chassis, engine, and interior structural components. These metal products are used for load-bearing, connecting, and supporting purposes, requiring high strength, high precision, fatigue resistance, and long-term reliability to ensure the structural stability and driving safety of the entire vehicle.

We are committed to providing the highest quality precision metal parts manufacturing services, including precision casting, investment casting, sand casting, and CNC machining. We offer customized solutions, and before mass production, we will provide a free sample for your testing and confirmation.

Features: Investment casting has high precision, can adapt to complex shapes, has smooth surface and little material waste.

Applications: Aerospace, precision machinery, automobiles, medical equipment, etc.

Features: Uses sand mold, which is low in cost and suitable for large and complex-shaped metal castings.

Applications: Automotive parts, mechanical structural parts, large castings.

Features: High precision, complex parts, and mass production.

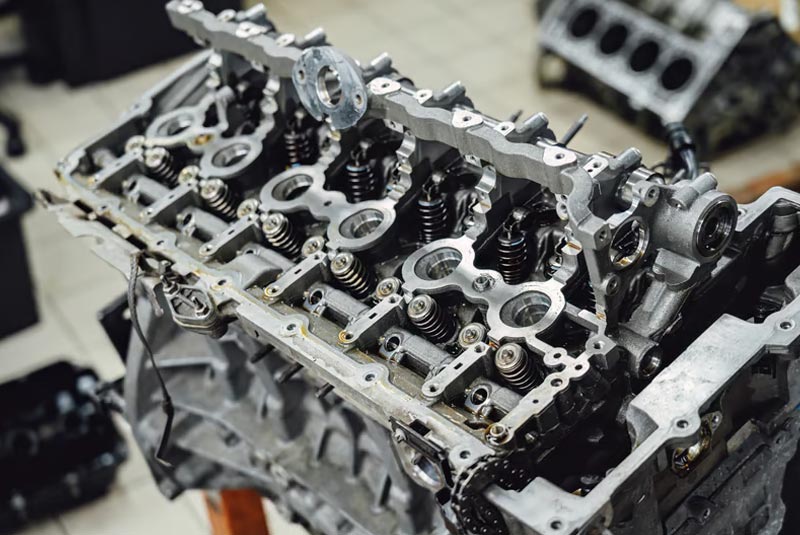

Applications: Molds, medical device parts, aluminum alloy engine cylinder blocks/cylinder heads.

Body Structure Components: Door brackets, hood supports, roof frame, body side beams, etc.

Chassis and Suspension Components: Longitudinal beams, crossbeams, suspension brackets, mounting brackets, etc.

Powertrain and Engine Components: Engine mounts, transmission mounts, oil pan, radiator brackets, etc.

Interior and Functional Support Components: Dashboard support, seat brackets, door panel supports, etc.

Safety and Protection Components: Impact beams, protective plates, energy-absorbing structural components, etc.

Suitable for body panels and general support components; low cost and good processability.

Used for chassis, suspension, and critical load-bearing components, ensuring strength and fatigue resistance.

Suitable for lightweight body and support components, balancing strength, corrosion resistance, and weight reduction requirements.

Used for chassis parts or exhaust system support components requiring high corrosion resistance.

Used for engine and transmission components requiring high temperature resistance or special wear resistance.