Spring manufacturing is a high-precision manufacturing process for producing elastic components from various materials and in diverse shapes.

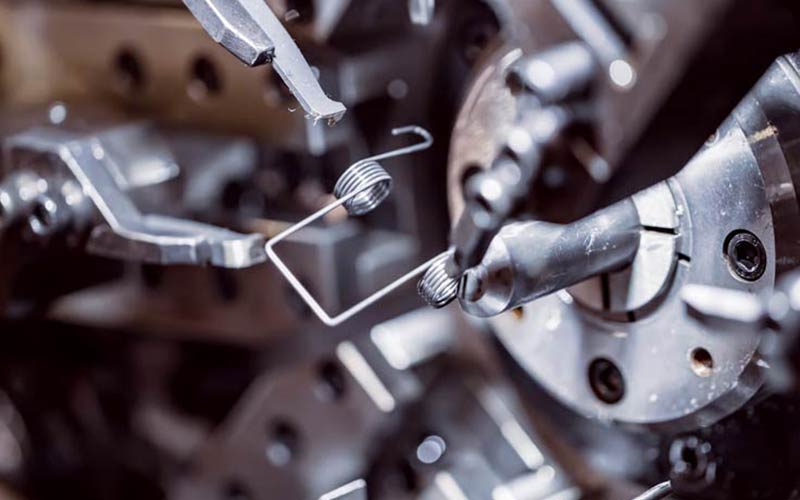

Spring manufacturing involves winding, stretching, straightening, heat treatment, and surface treatment of steel wire or strip on specialized equipment to produce various elastic components used for energy storage, cushioning, force transmission, or positioning. Spring manufacturing can produce helical springs, compression springs, extension springs, torsion springs, and special shaped springs.

Spring manufacturing is suitable for various compression, extension, torsion, and shaped springs, covering mechanical, automotive, aerospace, electronics, home appliances, medical devices, and hardware/outdoor industries, meeting both single-piece customization and mass production needs.

Used in pressure-bearing or energy storage devices

Used for connecting, positioning, or tensile applications

Used for rotation or torque transmission

Springs with special design structures, such as oval, square, or coiled edges

Small, precision helical springs

For rapid prototyping or springs made from special materials

Provides reliable mechanical performance

Spiral, tension, torsion, and custom-shaped springs

Steel wire, alloy wire, stainless steel wire, and special alloys

CNC equipment ensures batch consistency

Corrosion resistance, wear resistance, or decorative requirements can be met

Single-piece prototyping and large-scale production available

Get a free consultation from our casting experts now.

Commonly used materials include high-carbon steel wire, alloy steel wire (such as 60Si2Mn, 65Mn), stainless steel wire (304, 316, 17-7PH), copper wire, titanium alloy wire, etc.

Compression springs, extension springs, torsion springs, helical springs, irregularly shaped springs, and custom-designed springs.

High dimensional accuracy and repeatability can be achieved through CNC winding, straightening, and end treatment.

Yes, we support custom springs with helical, elliptical, square, rolled edge, and special structures.

Most springs require heat treatment (such as quenching and tempering) to improve strength and toughness. Surface treatments may include polishing, shot peening, painting, phosphating, or electroplating to enhance wear resistance and corrosion resistance.