Brazing is a metal joining process suitable for dissimilar metals or complex structural parts.

Brazing is a metal joining process that creates a strong metallic bond by heating the joint surfaces and using a filler metal (solder) with a melting point lower than that of the base metal, without melting the base metal itself. It is widely used for sealing, structural fastening, and creating electrically and thermally conductive connections between metal parts.

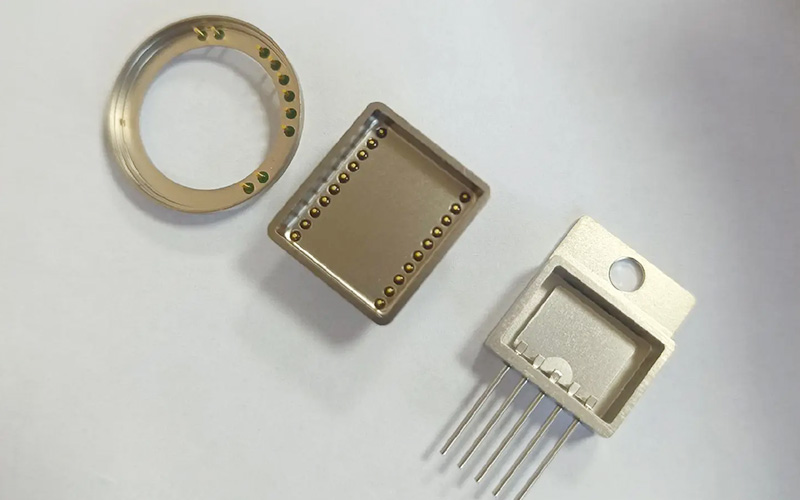

Ceramic welding is a specialized joining technology that reliably connects ceramics to metals or ceramics to other ceramics. It commonly employs processes such as brazing, active metal brazing, diffusion welding, or laser welding to achieve high-strength, high-temperature resistant, corrosion-resistant, and hermetically sealed connections.

This process involves softening, flowing, and densifying glass powder at high temperatures to form a continuous, dense body or to achieve reliable bonding between glass and materials such as metals and ceramics. It offers airtight sealing, electrical insulation, and high-temperature resistance.

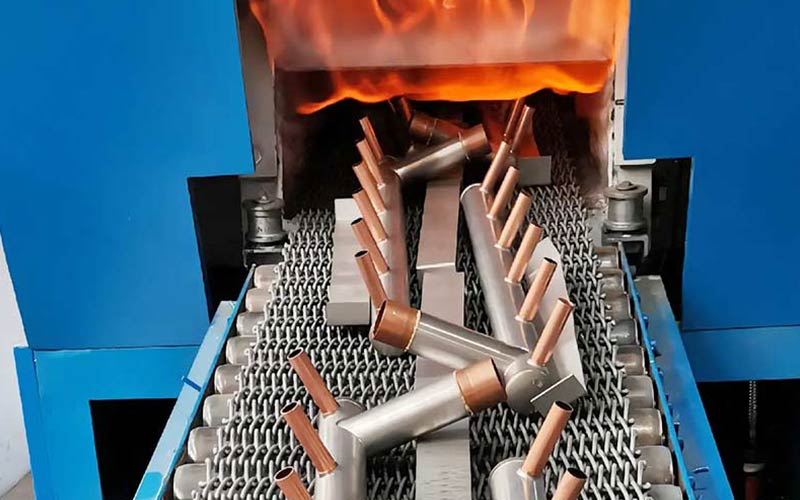

Brazing is suitable for thin-walled pipes, dissimilar metal joints, and small parts with complex structures, covering industries such as machinery, automotive, electronics, plumbing and valves, aerospace, and hardware, accommodating both mass production and customized small-batch manufacturing.

Copper tubes, aluminum tubes, radiator tubing

Brackets, frames, connecting plates

Electronic heat sinks, connectors, instrument housings

Copper-aluminum, copper-steel, nickel alloy-steel, etc.

Parts with multiple gaps, multiple holes, and irregular joints

Small to medium-scale batch production and rapid prototyping parts

Maintains the original mechanical properties of the parts.

Can connect dissimilar metals or complex-shaped parts.

Achieves airtight, watertight, or liquid-tight joints.

Small joint size variation and low deformation.

Induction brazing and reflow brazing are suitable for mass manufacturing.

Low-temperature brazing reduces the heat-affected zone.

Get a free consultation from our casting experts now.

Yes, brazing is suitable for joining various dissimilar metals such as copper-aluminum, copper-steel, and nickel alloy-steel.

Commonly used base materials include steel, cast iron, copper and copper alloys, aluminum and aluminum alloys, nickel-based alloys, titanium alloys, etc. The filler metal is selected to have a melting point lower than that of the base material.

Brazing is often used for thin-walled tubes, plates, and small load-bearing structural components. It can also be used for small to medium-sized irregularly shaped parts.

Brazed joints have high strength and can meet structural fixing requirements; they also possess good airtightness and liquid tightness, making them suitable for pipelines and sealing parts.

Brazed parts can usually be used directly, but depending on accuracy or assembly requirements, some parts may require trimming or cleaning of residue.